Cold Chain Logistics: Management Challenges & Solutions

The supply chain is a term used to describe all the components required to transport goods from beginning to end, from production to the end...

9 min read

BUKU Marketing

:

May 17, 2023 1:00:00 PM

BUKU Marketing

:

May 17, 2023 1:00:00 PM

Ecommerce represents one of the fastest-growing retail market segments. In 2022, Statista estimated eCommerce sales to top $5.7 trillion, and the last few years surpassed even the most far-seeing analysts' predictions. When the world went into lockdown, people turned to online shopping in unprecedented numbers

Table of Contents

1. Meeting The Demands Of Modern Consumers:

How 3pl Keeps Up With The Rise Of Ecommerce

2. The Future Of Logistics:

Maximizing Efficiency And Minimizing Costs With Automation And AI

3. Sustainable Practices Are Crucial For 3PL Success

4. Revolutionizing Urban Logistics:

Innovations And Trends Shaping The Future Of Last-mile Delivery

5. The Increasing Importance Of Data And Analytics In Logistics

6. Industry Shifts Are Changing How 3PLs Evolve And Predictions

7. Final Thoughts

Add to that the rapid adoption of internet use in general (5.3 billion global users in 2022, up from 4.9 billion the previous year), and you’ve got an industry that is changing at a fantastic rate.

All that growth has forced the adoption of solutions to help eCommerce businesses keep up and compete. Enter third-party logistics.

And it’s not just the eCommerce retailers that have had to adapt. 3PLs have undergone rapid growth alongside the eCommerce market, providing businesses with faster shipping, flexible delivery options, and improved technology.

All this growth and expansion have given eCommerce businesses the means to compete with even the most prominent players in the online retail segment, like Amazon, which commands 37.8% of the market share.

This article will look at how 3PLs adapt to keep up with a rapidly changing industry and the tools they are implementing in their operations to help eCommerce businesses better manage their logistics and define the future of third-party logistics.

As online shopping has become more popular, the online consumer has become more demanding. Part of this can be attributed to the "Amazon Effect." With a dominating hold over the eCommerce market, other retailers have had to stop and ask why.

What makes Amazon popular and drive so many customers to their site before others?

The other part of the equation is Amazon's ability to offer fast, flexible, and affordable delivery options. Amazon has created a population of online shoppers who simply expect same-day or next-day delivery options.

Businesses that want to compete have had to search for solutions that allow them to offer the same to their customers.

Today’s online consumers have steep demands regarding their shipping and delivery options. And Amazon has conditioned them to expect certain offerings when they reach a checkout page. 90% of online shoppers expect 2–3-day shipping, and around 30% expect the option of same-day delivery.

To simplify the problem, consumers expect fast and accurate shipping options at affordable prices. And while many are willing to pay a premium for expedited delivery, a more significant percentage wish for free shipping options to be included in the mix.

And these online shoppers have no problem abandoning a cart and heading to Amazon if those options aren’t offered.

These high consumer expectations have forced eCommerce stores to rethink their logistics and turn to 3PLs in huge numbers as a solution. This growth has accelerated the development of 3PLs and changed the future of 3PLs.

3PLs are implementing new and improved technology and processes into their operations to keep up with this expansion and compete with market players like Amazon few of the ways 3PLs are changing the face of logistics are:

Just like many other industries, the future of third-party logistics is automated. Already, 3PLs are using automation and robotic technologies in their day-to-day operations to increase speed and accuracy for their customers. Here’s how they’re doing it and why it matters.

Today’s fulfillment centers look much different than just a few short years ago. Walk into any fulfillment center, and you will see a plethora of automated technologies that employees use to pick orders, scan merchandise, track, and report inventory, and move goods around – just to name a few.

3PLs have found that robotics and AI are efficient ways to make their supply chains more resilient. And they are using these technologies to offer better options to their customers, often at a lower cost to everyone involved.

Here are a few examples of how robotics and AI are changing how 3PLs do business:

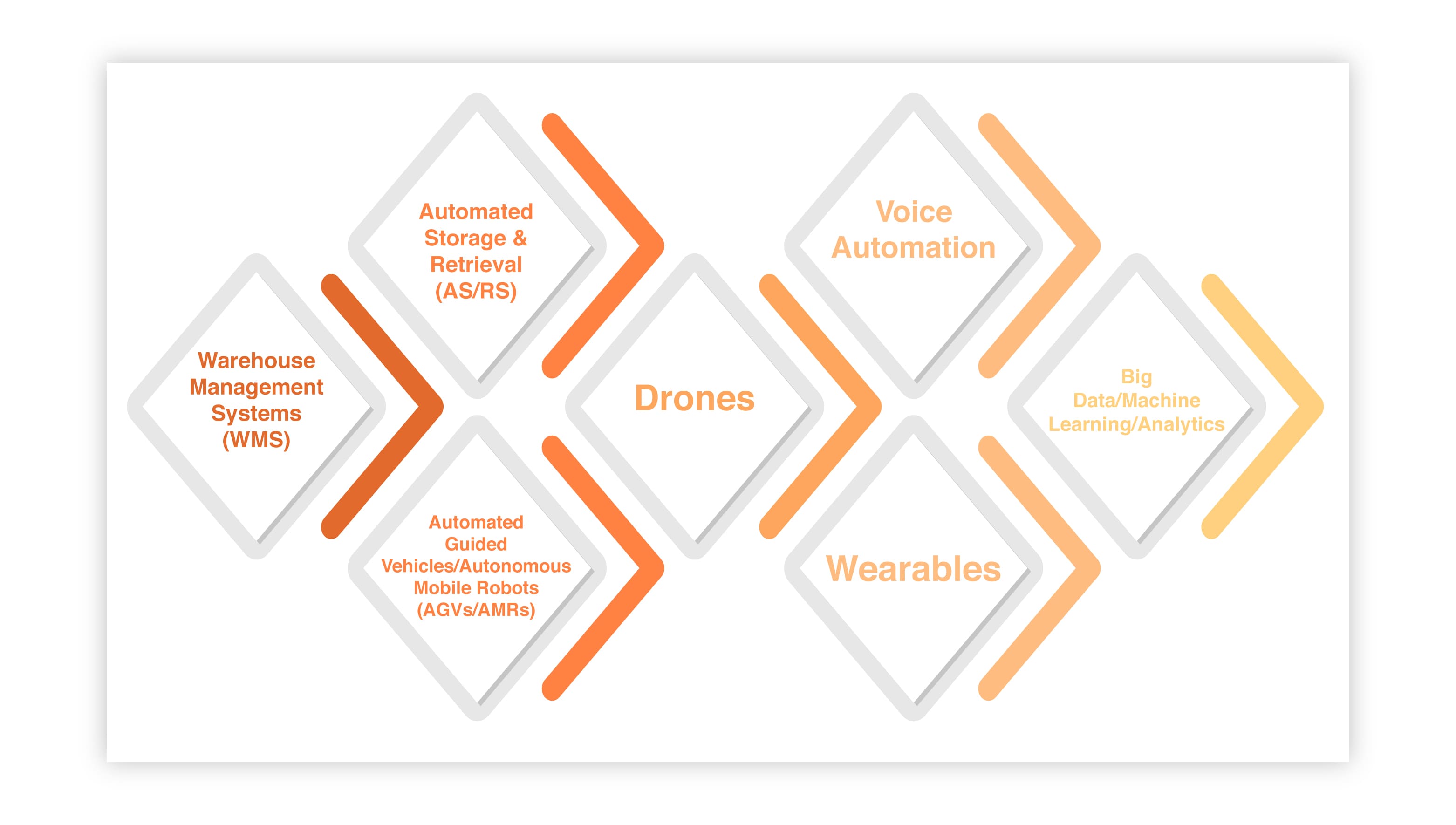

Warehouse Management Systems (WMS) – Today's warehouses and fulfillment centers include all-encompassing automation systems. The Internet of Things, or IoT, has enabled industries like 3PLs to digitize their operations, providing technology that links departments together and lowers costs, all while boosting productivity and efficiency.

Automated Storage and Retrieval (AS/RS) - Cutting the required manual labor to run an efficient fulfillment center is key to keeping up with demands. Automated storage and retrieval systems integrate directly with the WMS and are used to automatically pick and retrieve the correct products from the warehouse.

Automated Guided Vehicles/Autonomous Mobile Robots (AGVs/AMRs) - Today’s fulfillment centers use autonomous vehicles and robots to move goods around the warehouse without human operation.

Drones – Also referred to as Unmanned Aerial Vehicles (UAVs), drones are capable of snapping pictures of inventory and assisting with picking products using cameras and sensors, saving warehouse workers practical steps.

Voice Automation – Employees can use voice commands and prompts to help them determine where products are in the warehouse and exactly how to get there.

Wearables – Mobile devices worn or carried throughout the warehouse help employees perform numerous tasks, such as scanning inventory, and increase productivity and efficiency.

Big Data/Machine-Learning/Analytics - With machine learning and integrated automation, fulfillment centers can provide customers with real-time data regarding their business. From inventory management, predictive ordering, and more complete data regarding shipping and delivery, 3PLs can provide useful information and analytics that help customers better understand and optimize their logistics operations.

Another trend that encompasses pretty much all industries, as well as the future of 3PLs, is sustainability. Logistics and supply chain operations have long been considered big offenders for green and environmentally responsible operations.

With many 3PLs turning toward sustainability to protect the planet, reduce costs and build a more solid future, that reality is a thing of the past.

Sustainability refers to the use of improved processes and regulations to reduce the environmental impact of an activity. For 3PLs, sustainability means seeking environmentally friendly solutions to existing problems and finding better ways to complete daily processes.

Green Logistics is expected to grow at a rate of around 6.10% through 2028 and was worth an estimated $1,038.5 billion in 2021. That number is likely to top $1481.5 billion by the decade's end.

These statistics show that green logistics and sustainability efforts are not a trend but a new way of doing business that 3PLs must adapt to compete.

The reasons why companies of all kinds are seeking a more sustainable future are multi-faceted. And the benefits of seeking sustainable solutions far outweigh the risk of not doing so.

Consumer Attitudes – The younger generation puts much more importance on environmental issues and demands transparency from the companies they do business with. 86% of consumers list transparency as one of the biggest factors they consider when choosing a company to do business with.

Investment Attitudes – Investors are becoming increasingly nervous about doing business with companies not implementing sustainability measures. 85% of investment managers believe that businesses that fail to invest in sustainable logistics will lose value, meaning they’re less likely to take a risk on investing.

Cost-Savings – Investments usually cost money, but smart investments also provide a positive ROI. That’s what happens when companies invest in sustainable supply chains. 67% of business executives report that sustainable supply chains have cut costs because of increases in efficiency.

The future of third-party logistics offers fast, efficient, and affordable shipping and delivery solutions. Gone are the days when waiting a week or more for delivery was acceptable for consumers. 3PLs are looking for ways to improve their operations, especially regarding last-mile delivery and urban logistics.

Last-Mile Delivery/Last-Mile Logistics – These terms refer to the final step in the logistics process when goods are delivered from the fulfillment center to the consumer. Last-mile delivery is a process that involves partnerships between 3PLs and carrier companies.

Urban Logistics – Urban logistics is a broad term that encompasses many moving parts of the supply chain and refers to the pieces used in orchestrating those moving parts in scheduling and carrying out delivery, storage, and other processes related to logistics.

As eCommerce has grown and 3PLs have taken on greater importance in the supply chain, improvements were needed to facilitate the number of orders and deliveries.

A single eCommerce retailer scheduling deliveries from their basement has a simple path to success – find a carrier who can deliver where a package needs to be delivered, schedule the delivery, and get the package to the carrier. Done.

A 3PL dealing with hundreds of deliveries has a much more complicated road to follow if they want to maintain profitability. That means dealing with multiple challenges that have arisen as eCommerce has exploded.

To figure out the problem(s), supply chain partners are looking to technology once again. Several tools can help speed the last-mile delivery process and smooth out the wrinkles in urban logistics.

Last-mile delivery often requires making many stops in a concise amount of time and spread over a busy, urban area. Finding the most cost-efficient route is essential for keeping costs in check, and that requires using GPS and navigation technology.

The efficiency of a delivery route relies on accurate information. If an address is entered incorrectly at any point in the process, deliveries could be delayed, interrupted, or incomplete. Drivers and fleet managers need efficient technology to help them avoid errors in the first place and the ability to communicate to solve route problems in real-time quickly.

Using navigation to plan a route can reduce the time it takes to complete last-mile deliveries. But even navigation systems can’t foresee everything. Traffic congestion, construction, the operating hours of businesses and warehouses, and careful planning can help avoid delays and plan for the most timely and efficient route.

Last-mile delivery is a challenge that is only getting larger as the number of online shoppers grows and grows. And once again, 3PLs and carriers are looking to technology to help them find solutions.

Drones are one example of how technology makes last-mile delivery faster, more sustainable, and less dangerous.

A recent estimate put the value of the drone package delivery market at an estimated $39 billion by 2030.

Autonomous delivery vehicles are a newer and still-in-development technology that some believe will soon change the face of logistics. Autonomous vehicles don’t need a driver, and although some find it hard to believe, they are thought to be safer on the roads than human-operated vehicles.

If you’re not catching on by now, let’s reiterate that the future of third-party logistics is automated and uses technology to its fullest potential.

Most people are familiar with the images of fulfillment center workers using mobile devices to scan goods and robots moving goods around the warehouse. But some don’t realize the amount of technology running the show in the background.

Data and analytics solve many problems at once, and 3PLs are using this information to help their customers make better decisions regarding their business. A 3PL is no longer simply a provider of picking and delivery services.

They also represent a crucial partner in the supply chain, inventory management, ordering, and forecasting processes. And technology, data, and real-time analytics are facilitating that shift.

Demand forecasting is one of the most useful pieces of information that 3PLs can offer to eCommerce businesses. By providing a big-picture view of inventory, purchasing, orders, market trends, and consumer insights, 3PLs can help businesses make better decisions.

Demand forecasting helps avoid stockouts and prevents unnecessary inventory build, saving businesses money and ensuring customers are always satisfied, and orders are always fulfilled.

With so many moving parts in a supply chain, 3PLs face the unique challenge of finding ways to bring data together in a consolidated and understandable fashion. Software, technology, and integration are helping with the problem, but there is still room to grow.

Ready for some big numbers? The future of third-party logistics is promising, and industry expectations put its value at more than $1.3 trillion by 2026. The rise in popularity of eCommerce is partially responsible for driving that growth, but 3PL providers are doing their share of the hard work to move the industry forward as well.

Meeting consumer expectations is a requirement for any successful business. In the eCommerce industry, those expectations have transformed dramatically over a concise period, and 3PLs are scrambling to keep up.

Fast, one-day, or same-day shipping is a significant driver of this transformation. It’s pretty much a required offering to compete with the prominent market players. Consumer demand for fast and affordable (or even free) shipping is so great that 9 out of 10 online shoppers say it affects their purchasing decisions.

We mentioned sustainability as a driver for change in the 3PL industry. Much of that has to do with consumers demanding that the companies they do business with are as eco-friendly and environmentally friendly conscious as possible. 60% of consumers say they have changed their purchasing habits to better align with sustainability.

The Covid-19 pandemic taught supply chain partners and 3PLs some hard lessons. With whole industries affected by shutdowns, delays, and labor shortages, 3PLs came to some realizations shaping how logistics grows going forward.

A supply chain that can withstand events like these is crucial for 3PLs who want to come out the other side. Real-time data and predictive analytics are one way that 3PLs can navigate these challenges by helping their customers and themselves weather disruptions. Diversifying their partnerships and planning are vital at this point.

No getting around the rise of technology and AI in industry, including 3PLs. Companies are no longer dragging their feet in implementing new technologies.

Still, instead, they are embracing the many ways that advanced technology, and AI can increase productivity, enhance efficiency, improve processes, and cut costs. That’s not likely to change any time soon.

The future of any industry is wide open for progress and change. The same holds for the future of third-party logistics. With rapid growth spurring the need for improvement, 3PLs are digging in and bracing for a future that will likely look a lot different than it did just a few years ago or even today.

Warehouse automation is leading the charge, and 3PLs are now fully automated, integrated systems where technology makes every task faster, easier, and more accurate.

Data and analytics come in second, providing 3PLs the power to virtually see into the future and make better decisions for their customers - and help customers make better decisions for their businesses.

And, of course, a push to become more sustainable also drives change within the industry, as it should.

Finding more ecologically responsible ways to do business, optimizing efficiency in last-mile delivery, and providing more transparency for customers are all necessary steps toward the future of the logistics industry.

What’s next? Time will tell, but there’s a strong likelihood that technology, data, and a need for greater efficiency will be leading the way.

The supply chain is a term used to describe all the components required to transport goods from beginning to end, from production to the end...

A smart warehouse is a large building where raw materials and other consumer goods are stored using machines, computers, comprehensive software, and...

Direct-to-consumer (DTC) fulfillment is a strategy that helps brands sell and deliver their products directly to customers more efficiently while...