Cold Chain Logistics: Management Challenges & Solutions

The supply chain is a term used to describe all the components required to transport goods from beginning to end, from production to the end...

8 min read

BUKU Marketing

:

Sep 13, 2023 1:00:00 PM

BUKU Marketing

:

Sep 13, 2023 1:00:00 PM

A smart warehouse is a large building where raw materials and other consumer goods are stored using machines, computers, comprehensive software, and hardware tools to manage inventory, track shipments, and optimize warehouse operations to complete everyday operations previously performed by humans.

Table of Contents

Today, 80% of warehouses have no automation, and only 5% use technology sophisticated enough to be considered a smart warehouse.

However, the size of the global smart warehousing market is projected to be USD 24.96 billion in 2023 and USD 74.62 billion by 2030, rising at a Compound annual growth rate (CAGR) of 16.86%. So, while smart warehouses are not exactly famous today, the method is snowballing.

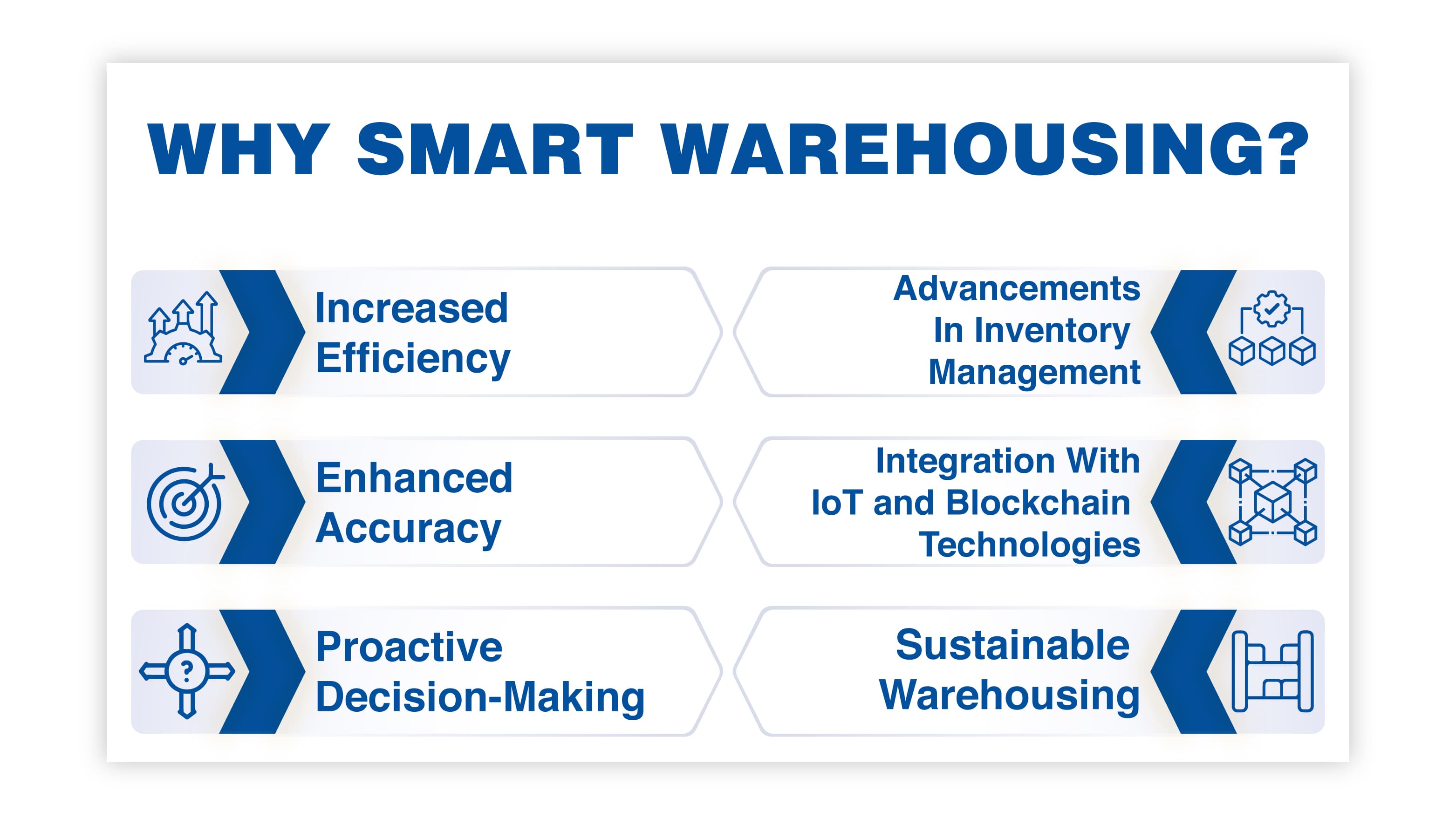

By automating data collection and analysis, smart warehouse systems provide real-time visibility into operations, enabling informed inventory, staffing, and shipping decision-making. These systems leverage IoT devices, automated systems, and data analysis software to streamline processes, improve efficiency, and reduce costs.

However, implementing a smart warehouse system may present challenges such as retrofitting, data security, and upfront investment.

By integrating cutting-edge technologies like robot palletizing, autonomous mobile robots, and real-time data analytics, you'll experience increased productivity and efficiency like never before.

Say goodbye to manual labor and hello to a world of freedom in your warehouse operations. It's time to embrace the benefits and best practices of smart warehousing.

Smart warehousing incorporates various vital technologies, such as Warehouse Management System (WMS), Automated Picking Tools, Automated Guided Vehicles (AGVs), Automated Inventory Control Platforms, AMRs, IoT, digital twins, and 5G, to optimize warehouse operations.

These technologies work together seamlessly to create a more efficient and productive warehouse environment.

Imagine walking into a smart warehouse where robots and other automated picking tools are busy palletizing goods precisely and quickly.

These robots are equipped with advanced algorithms to stack products securely and efficiently. Their help makes the palletizing process faster and requires less manual labor.

Not only that, but smart warehouses also utilize AMRs (Autonomous Mobile Robots) to handle tasks like picking and transporting goods within the warehouse. These little robots can navigate through the aisles effortlessly, ensuring that items are delivered to their designated locations accurately and promptly.

The Internet of Things (IoT) is another crucial technology in smart warehousing. It allows for real-time data collection from various sensors placed throughout the warehouse.

This data helps identify areas that need quick service or restocking. You can make informed decisions quickly by having this visibility into inventory levels and performance metrics.

Digital twins take things further by creating virtual replicas of physical assets within the warehouse.

This enables you to simulate different scenarios and optimize processes without disrupting operations. It's like having a 3D model of your warehouse that you can experiment with before implementing any changes.

And let's not forget about 5G connectivity and a proper WMS to take advantage of 5G benefits—the backbone of all these technologies in a smart warehouse. Its lightning-fast speeds and low latency ensure smooth communication between devices and inventory control platforms.

It enables real-time tracking of goods throughout the supply chain while increasing efficiency, accuracy, and productivity while reducing human error and labor costs.

When optimizing your warehouse operations, you'll experience increased productivity, improved accuracy, and enhanced customer satisfaction with smart warehousing technology.

Smart warehousing allows you to streamline your processes and save costs while meeting customer demands.

By implementing automated guided vehicles (AGVs) and RFID systems, you can optimize warehouse space, reduce material damage, increase inventory accuracy, and boost efficiency.

These advancements free up valuable time for your employees to focus on more meaningful tasks that require human expertise.

Additionally, innovative warehousing provides scalability to handle growing product influxes and new releases. You won't have to worry about outgrowing your current system or investing in additional fulfillment centers.

The compatibility of smart warehouse software with various platforms ensures seamless integration with other features and third-party logistics providers.

If you're looking for real-life examples of successful implementation, you'll find inspiration in companies like Amazon and Alibaba. These giants have revolutionized the concept of smart warehousing, showcasing the immense benefits it brings to businesses.

With their innovative use of automation, artificial intelligence, and advanced technologies, they have set new standards in the industry.

Amazon's fulfillment centers are a prime example of smart warehousing done right. By integrating robotics and AI-powered systems, they achieve unparalleled efficiency and accuracy in their operations.

From automated picking and packing processes to intelligent inventory management, Amazon has mastered maximizing productivity while minimizing errors.

Similarly, Alibaba's smart warehouses utilize cutting-edge technologies like IoT sensors and data analytics to optimize their supply chain. Their systems provide real-time visibility into inventory levels, allowing for proactive decision-making and seamless order fulfillment.

By leveraging these advanced tools, Alibaba has been able to meet customer demands swiftly and maintain high levels of customer satisfaction.

These companies' success stories demonstrate that implementing smart warehousing technology can truly transform your business operations.

By embracing automation and interconnected technologies, you can streamline your processes, increase productivity, reduce costs, and enhance customer service.

One exciting trend in the future of warehousing is the integration of artificial intelligence and machine learning algorithms to optimize inventory management.

This advancement brings a sense of freedom and liberation to the warehouse industry, allowing for more efficient operations and improved decision-making.

Here are some reasons why this trend evokes excitement:

More connected systems enable real-time data-sharing and analysis, leading to more efficient and optimized warehouse operations.

Integrating artificial intelligence and machine learning into warehousing operations provides great freedom in a world where efficiency and speed are paramount. It allows businesses to focus on growth opportunities rather than getting caught up in tedious manual tasks.

With optimized inventory management powered by AI, warehouses can embrace this exciting trend while enjoying increased productivity, accuracy, and flexibility. If you desire freedom in your warehouse operations, embracing this trend is worth considering.

Implementing smart warehousing involves integrating interconnected technologies to optimize warehouse operations and improve efficiency. You want the freedom to run your warehouse smoothly and efficiently; smart warehousing can help you achieve that.

You can streamline processes, reduce errors, and increase productivity by leveraging advanced technologies like robotics, the Internet of Things (IoT), and artificial intelligence (AI).

One best practice for implementing smart warehousing is to prioritize automation. Utilizing Warehouse Management Systems (WMS) will help automate inventory management, track items in real-time, and improve the accuracy of demand-driven manufacturing.

By automating tasks such as receiving, sorting, organizing, and shipping, you can minimize manual labor and free your staff to focus on more critical activities. Collaborative robots (cobots) can work alongside your employees to handle complex tasks effectively.

Another best practice is to ensure compatibility with various platforms and systems. Smart warehouse software should seamlessly integrate with your existing infrastructure to avoid disruptions in operations.

Barcodes provide a quick way to identify warehouse items.

Creating a barcode for each product or thing can help store employees know the quantity and number of items stored at specific locations in the warehouse. This way, you can choose the systems that work best for your business while benefiting from the advantages of smart technology.

Scalability is also crucial in smart warehousing. As your business grows or experiences fluctuations in demand, your warehouse needs to be ready to handle large influxes of products and new releases.

Using necessary inventory management systems, including software, to streamline the supply chain. Implementing scalable solutions ensures that you can adapt quickly without compromising efficiency.

Invest in your staff. A safe and secure working environment leads to better productivity and focuses on self-protection measures against workplace accidents. In addition, communication is critical.

With so much automation and technology, you want to ensure you communicate with your staff and maintain constant training to ensure employees are up to date on operations and technology.

Finally, keep the staff happy. With more technology comes more training. Staff turnover should be avoided, as the learning curve of a smart warehouse is different from a warehouse without automation, where the staff is easily replaced.

Depending on your chosen technology and your demands, a smart warehouse facility can cost anywhere from under $1 million to $25 million.

However, these automations soon pay for themselves, especially since labor expenditures typically account for nearly 65% of warehouse operating budgets. Still, warehouse automation can cut those costs by as much as 30%.

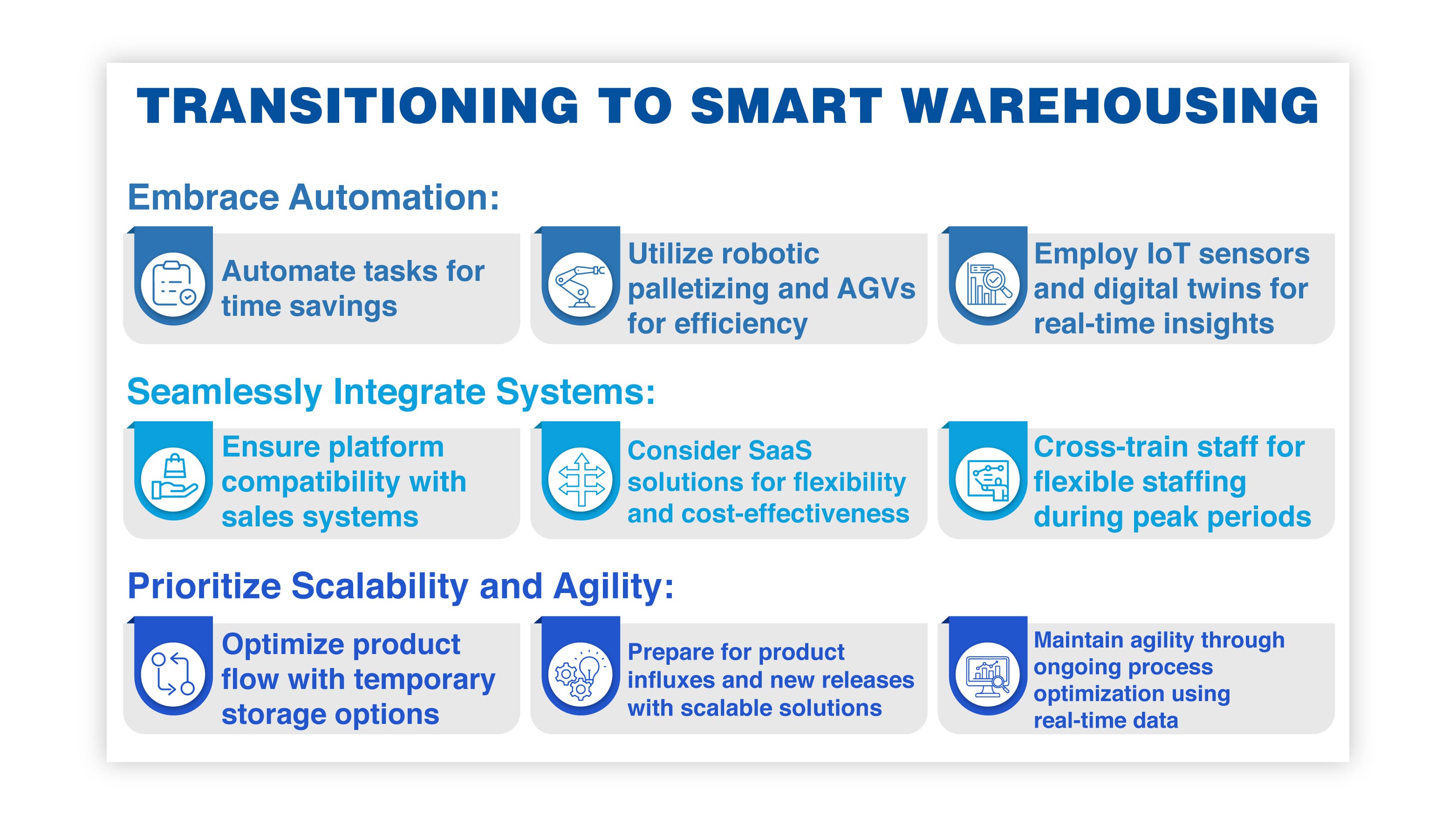

To ensure a successful transition to smart warehousing, it's essential to prioritize automation and seamlessly integrate your existing systems. This will allow you to fully embrace the benefits of this revolutionary technology while maintaining the freedom and flexibility you desire.

Here are some tips to help you make the most of your transition:

While there are some challenges to implementing smart warehousing, the benefits are clear. Businesses adopting smart warehousing will be well-positioned to compete in the growing global marketplace.

Implementing smart warehousing technologies can vary in cost depending on several factors, such as the size of your warehouse, the complexity of the system, and the specific technologies you choose to implement. Expenses can range from thousands to millions of dollars.

It's essential to assess your unique needs and budget before deciding. Consulting with experts in the field can provide a more accurate estimate based on your specific requirements.

Yes, smart warehousing systems can be customized to fit the specific needs of different industries. By leveraging interconnected technologies like IoT, robotics, and automation, these systems can be tailored to optimize warehouse operations according to your industry's unique requirements.

Whether in retail, manufacturing, or logistics, smart warehousing can adapt to your specific workflows and processes. This customization ensures that you have a solution that maximizes efficiency, productivity, and cost savings for your business.

Implementing smart warehousing may come with potential challenges or risks. These can include the initial investment cost, the need for employee training, and possible resistance to change. Integration with existing systems and platforms may also need to be improved.

Additionally, interconnected technologies and data management could be associated with cybersecurity risks.

However, by carefully planning and addressing these challenges, increased productivity, improved accuracy, enhanced customer satisfaction, and scalability make smart warehousing a worthwhile investment for businesses.

Transitioning from manual warehousing to smart warehousing typically takes time and planning. The transition duration can vary depending on factors like the size of your warehouse and the complexity of implementing new technologies.

Assessing your needs, conducting thorough research, and developing a clear implementation strategy are vital. By taking these steps, you can ensure a smooth transition that maximizes the benefits of smart warehousing for your business.

Various options are available regarding training and support for employees working with smart warehousing systems. Companies often provide comprehensive training programs to ensure you have the necessary skills and knowledge to operate the technology effectively.

Additionally, ongoing technical support is usually provided to address any issues or questions that may arise during implementation. This ensures that you feel supported and confident in utilizing the smart warehousing systems to their full potential.

Now that you have learned about smart warehousing and its benefits, it's time to embrace this game-changing technology. Keep your warehouse operations from falling behind in this fast-paced market.

Look to the future with open arms and unlock the potential of automated systems, real-time data, and seamless integration. Start implementing smart warehousing practices today and revolutionize your business operations.

The supply chain is a term used to describe all the components required to transport goods from beginning to end, from production to the end...

A smart warehouse is a large building where raw materials and other consumer goods are stored using machines, computers, comprehensive software, and...

Direct-to-consumer (DTC) fulfillment is a strategy that helps brands sell and deliver their products directly to customers more efficiently while...