Cold Chain Logistics: Management Challenges & Solutions

The supply chain is a term used to describe all the components required to transport goods from beginning to end, from production to the end...

8 min read

BUKU Marketing

:

Aug 23, 2023 1:00:00 PM

BUKU Marketing

:

Aug 23, 2023 1:00:00 PM

Simply put, cross-docking is a way to move products without storing them. It minimizes handling times and maximizes efficiency in the supply chain. Cross docking started in the 1930s and became popular as companies improved their supply chains.

Table of Contents

2. Challenges of Cross-Docking

4. Best Practices for Successful Cross-Docking

5. Choosing the Right Products for Cross-Docking

6. Cross-Docking vs. Warehousing

7. Cross Docking vs. Drop Shipping

8. Key Performance Indicators (KPIs) for Cross-Docking

9. Frequently Asked Questions (FAQ)

10. Cross Docking Can Save You Time, Labor, and Space

Walmart's implementation of cross-docking in the 1980s exemplifies its role in gaining a competitive edge. With the help of software, Walmart used this system to grow into the monster retailer they are today, with many other logistics and commerce companies following suit.

Today, cross-docking optimizes supply chain operations and increases efficiency in various industries.

This article discusses the advantages and difficulties of cross-docking and how it can improve supply chain and efficiency.

Cross-docking has many benefits: it reduces storage needs, eliminates large warehouses, increases efficiency in product movement, reduces distribution costs, and speeds up delivery times.

According to a report by McKinsey, over 90% of consumers expect two to three-day deliveries, so fast delivery is practically mandatory to stay competitive.

Cross-docking eliminates the need for ample storage space. Products are swiftly transferred from inbound to outbound transportation without storage.

This helps by reducing the need for big warehouses and eliminating warehouse costs. Cross docking alone can reduce supply chain costs by 6.4%.

Cross-docking makes product movement more efficient by consolidating and transporting full loads. This results in reduced handling times and improved operations.

Additionally, cross-docking helps lower distribution costs by eliminating many common and unnecessary steps such as storing and retrieving products from a warehouse.

Furthermore, cross-docking enables faster delivery times to customers. Products are moved directly from inbound to outbound transportation without delays or needing storage.

This helps them reach their destination faster and ensures timely order fulfillment while improving customer satisfaction.

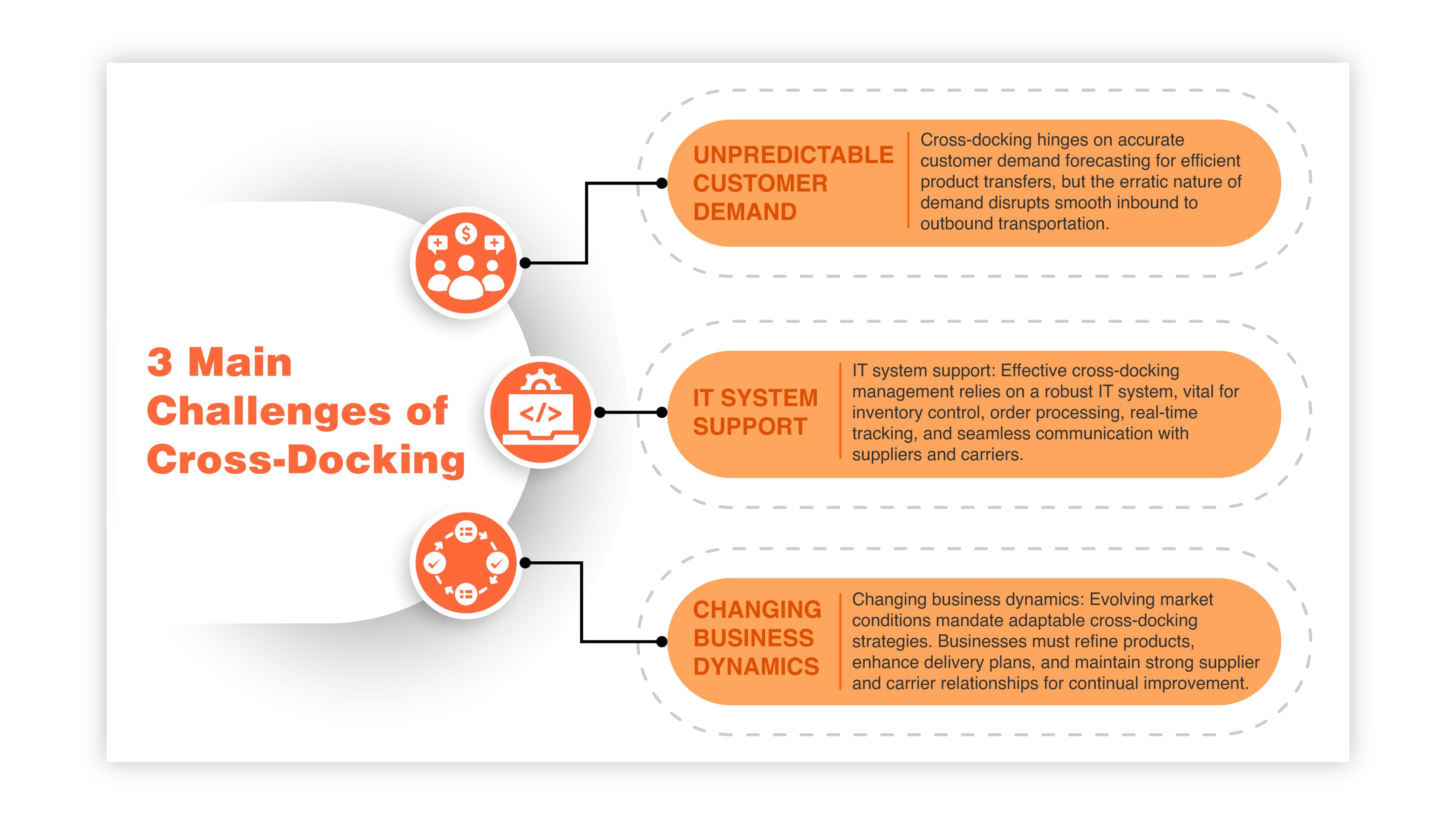

One of the obstacles faced in cross-docking is the need for reliable IT system support to ensure smooth operations and efficient tracking of products.

Cross-docking challenges can be broken down into three main challenges:

Customer demand is unpredictable, which affects product transportation between inbound and outbound.

The company needs to change its products, improve delivery plans, and stay connected with suppliers and carriers to improve things.

While there are more challenges than those listed such as facility design, shelf-life, and ROI, these are the main problems to be overcome.

To overcome these and other challenges, companies must use strategies like improving demand forecasting, investing in IT, collaborating with partners, and constantly monitoring performance.

Businesses can enhance their cross-docking operations, save money, work faster, and be more efficient by facing these challenges directly.

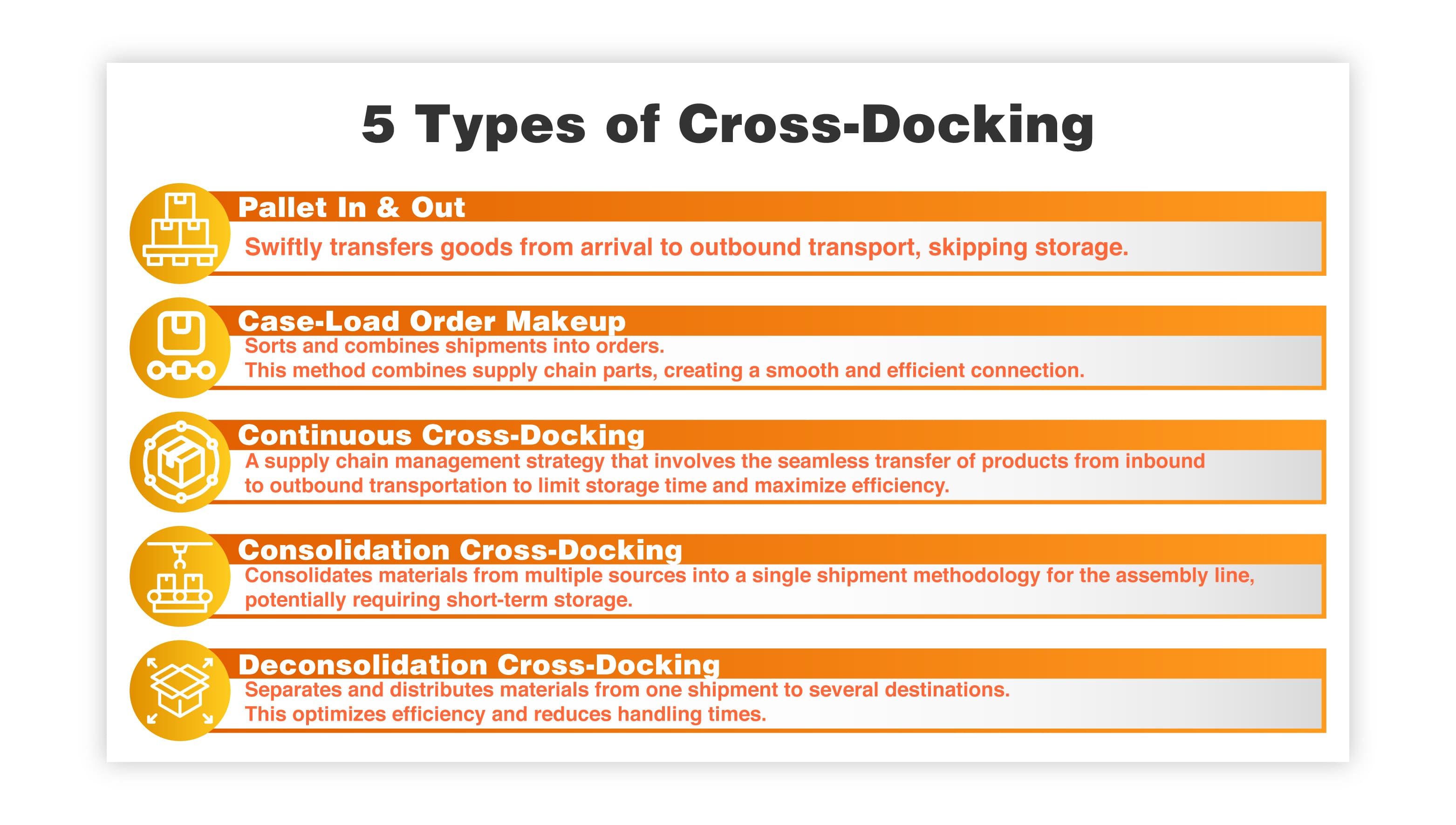

While there are several types of cross-docking, we will focus on the five main types of cross-docking procedures.

Here are some of the most common forms of cross-docking.

Pallet In & Out cross-docking is a logistics strategy that moves goods from arrival to outbound transportation without storing them. This method improves supply chain efficiency by reducing the time spent in warehouses, using workers efficiently, and controlling inventory costs.

This method coordinates incoming pallets with outgoing orders to streamline material flow and speed distribution.

The result is a well-coordinated movement of goods that matches the demand and helps with efficiency.

Case-Load Order Makeup cross-docking sorts and combines shipments into orders. This orchestrated process efficiently synchronizes inbound products with outbound orders, enabling seamless distribution and reducing unnecessary handling.

It helps move items from arrival to dispatch fast, improves the way inventory is used, and speeds up order fulfillment. This method combines supply chain parts, creating a smooth and efficient connection.

Continuous cross-docking is a supply chain management strategy that involves the seamless transfer of products from inbound to outbound transportation to limit storage time and maximize efficiency.

In continuous cross-docking, products are received at a facility and then sorted and loaded onto transport for immediate delivery.

This plan removes the need to store things during transportation, so orders are filled faster and handled less.

Consolidation cross-docking involves consolidating materials from multiple sources into a single shipment methodology for the assembly line, potentially requiring short-term storage.

This type of cross-docking offers several advantages like improved efficiency, flexibility, and delivery times all while saving money.

Deconsolidation cross-docking is a strategy in supply chain management. It separates and distributes materials from one shipment to several destinations. This optimizes efficiency and reduces handling times.

A consolidated shipment is received at a cross-docking facility and then quickly broken down into smaller parts. The products or shipments are sorted and loaded onto vehicles for direct delivery to their destinations.

Deconsolidation cross-docking eliminates the need for storage and warehousing between the inbound and outbound stages of transportation, allowing for faster order fulfillment and reduced inventory holding costs.

Using this strategy is especially helpful in industries with unpredictable demand and needing to deliver quickly.

Some things are essential for successful cross-docking. Some factors include the warehouse's shape, the number and placement of dock doors, and the inbound and outbound transportation schedule.

The shape of the warehouse is vital for efficient cross-docking. It affects the material flow and accessibility.

Also, the number and placement of dock doors to make loading and unloading smooth.

Having a good transportation schedule is important for getting products delivered on time.

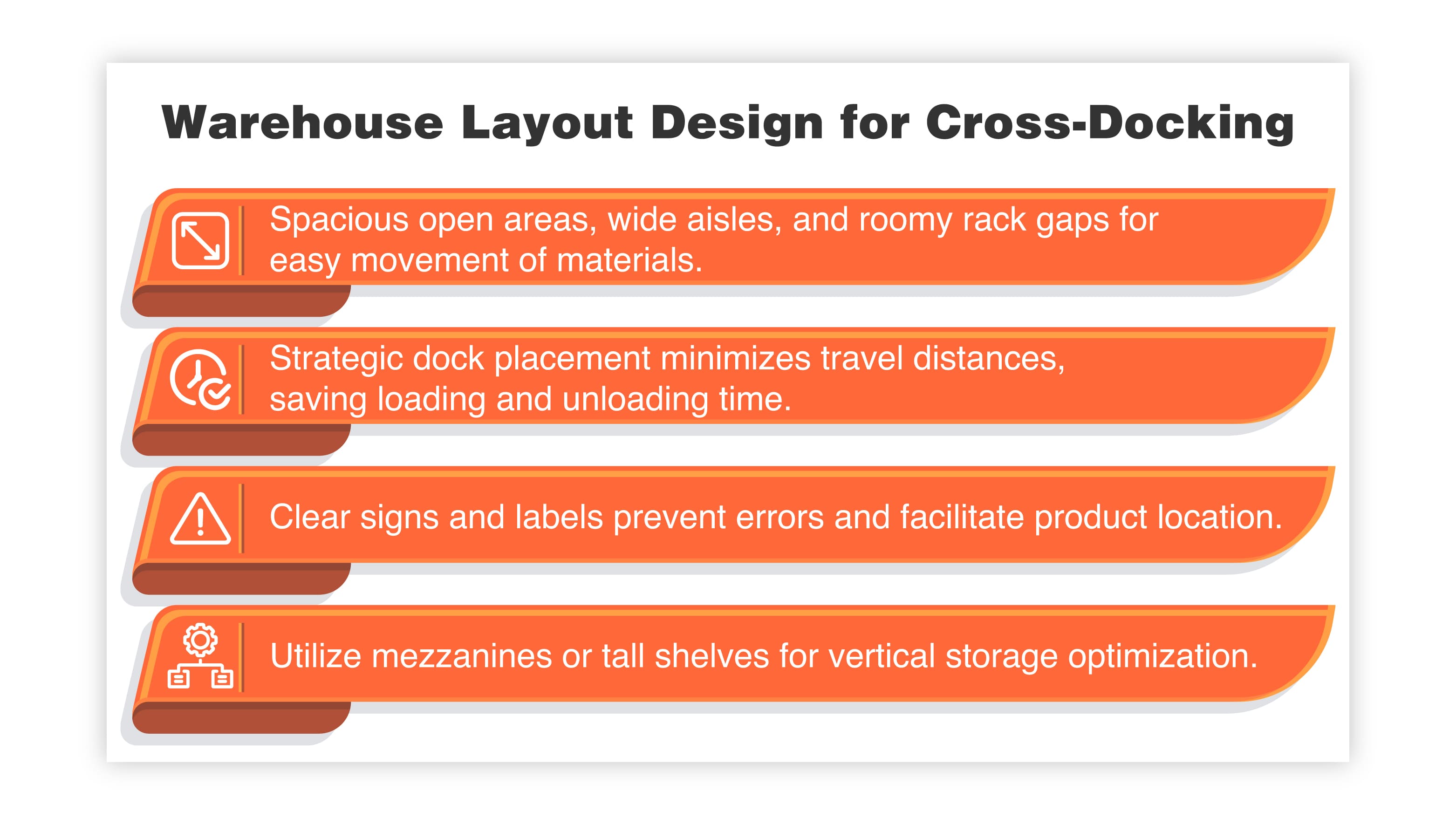

The warehouse's shape and layout are important for optimizing cross-docking and product movement.

A good warehouse helps things move smoothly and makes work faster, which increases productivity.

The following factors contribute to a practical warehouse layout:

When planning a warehouse, it's crucial to consider the number and location of dock doors. This helps make cross-docking operations efficient and keeps shipments flowing smoothly.

Having enough dock doors is important for quickly loading and unloading. This helps avoid long waits and delays. Strategically placing dock doors in the warehouse layout can make material flow smoother and reduce worker and equipment travel distances.

Inbound and outbound transportation schedules are crucial to successful cross-docking operations. The task requires planning and coordinating shipment arrival and departure times for smooth transfers.

Companies can improve the supply chain by creating a good transportation plan. This helps reduce waiting times, handling costs and improves the flow of goods.

Other considerations for successful cross-docking while in operation include:

When selecting products for cross-docking, consideration should be given to items with stable and constant demand, pre-packaged and ready-to-sell products, and oversized or difficult-to-ship items.

These things are important because cross-docking involves quickly transferring products from inbound to outbound transportation with little storage.

Cross-docking works well for high-demand items because they don't need storage and can be moved easily.

Products that are pre-packaged and ready to sell are also good for cross-docking. They can be moved between transportation without extra handling or packaging.

Cross-docking is also helpful for large or hard-to-ship items since it avoids the need for special storage or handling equipment. Businesses can improve efficiency in the supply chain by considering these factors for cross-docking.

Cross-docking and traditional warehousing differ in how long products are stored in the supply chain.

In cross-docking, products are moved rapidly from one transportation point to another without much storage in between. This approach minimizes handling times and maximizes efficiency in the supply chain.

Traditional warehousing, on the other hand, involves storing stocks of products in a warehouse for delivery to customers. These warehouses typically have larger areas dedicated to the long-term storage of inventory.

More flexibility in meeting customer demands and managing supply fluctuations comes with extra costs. These costs include maintaining a large inventory and organizing storage space.

Cross-docking offers several advantages over traditional warehousing.

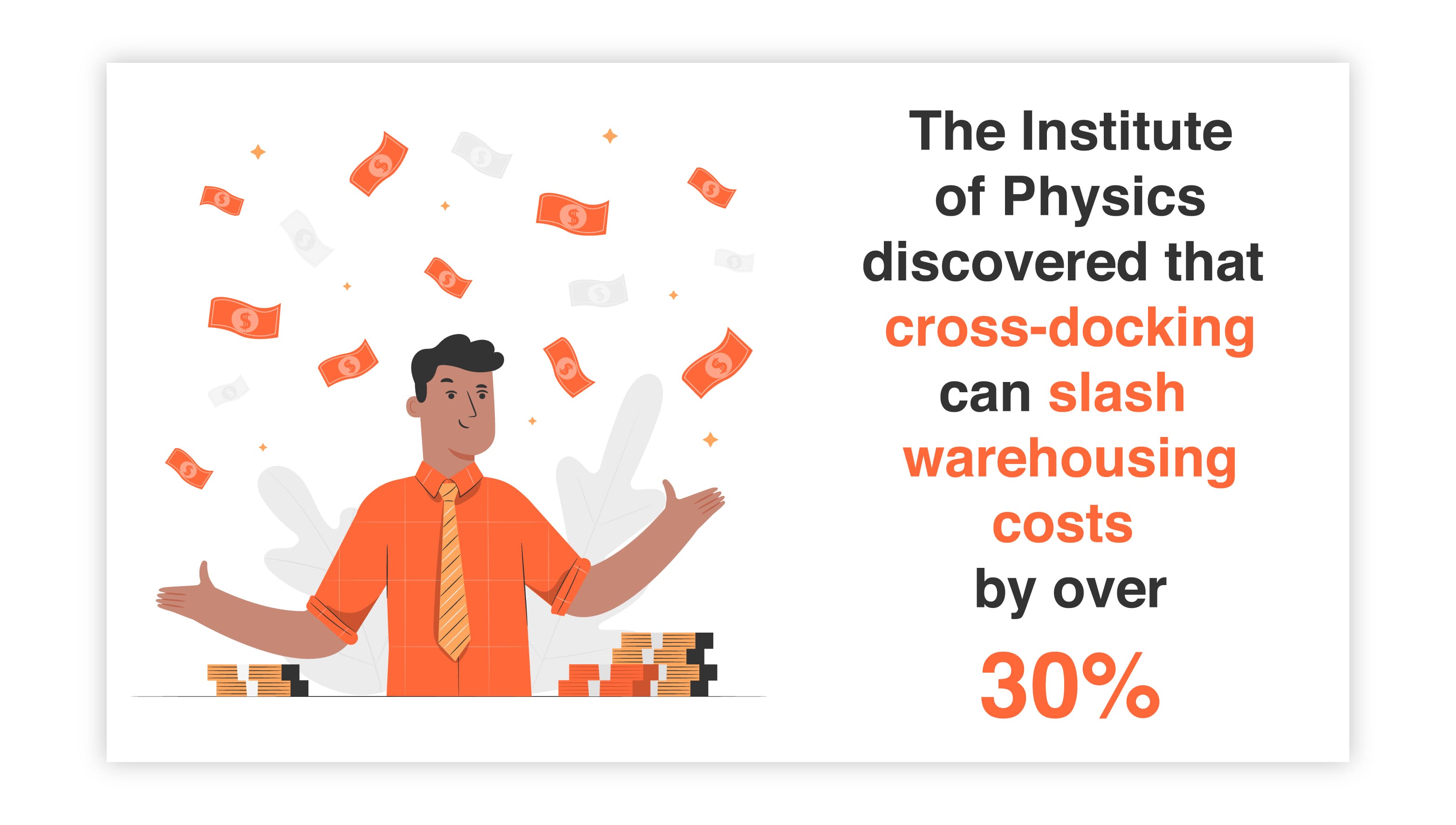

Firstly, it reduces costs by eliminating the need for large warehouse areas and minimizing product touches. A study by the Institute of Physics found that businesses can effectively cut warehousing costs by 30% or more using cross-docking.

Also, shipping is made easier because products can be combined and transported in large quantities, which lowers distribution expenses. Cross-docking helps products reach customers faster by avoiding storage and picking delays.

The main distinction between cross-docking and drop-shipping is that there is no storage or picking operations, as cross-docking involves direct shipping of goods without any warehousing while drop-shipping entails the supplier sending goods directly to customers without holding them in stock.

In cross-docking, products are received at a distribution center or hub. They are then quickly sorted and loaded onto trucks for delivery. This process eliminates the need for storing products in a warehouse and allows for faster order fulfillment.

On the other hand, drop-shipping involves the supplier shipping products directly to customers after receiving an order from a retailer. The supplier does not hold inventory or engage in handling or storing goods.

Instead, they rely on their network of manufacturers or wholesalers to fulfill orders on their behalf. Drop-shipping has advantages like lower inventory costs and more options for products.

Cross-docking and drop-shipping provide efficient ways to streamline supply chain operations by eliminating unnecessary steps and reducing costs associated with warehousing and inventory management.

Businesses should carefully consider their needs and logistics when choosing an approach.

Businesses can use Key Performance Indicators (KPIs) to measure the efficiency and accuracy of cross-docking operations. These indicators track throughput time, order accuracy, and on-time delivery.

The KPIs give valuable insights into cross-docking performance. Businesses can find areas to improve and optimize their supply chain by closely tracking vital KPIs, and adjusting accordingly.

The time it takes for products to move through the cross-docking process is called throughput time.

A shorter throughput time indicates higher efficiency in handling and transferring products.

Order accuracy is a critical metric that shows how often orders are processed correctly.

It measures the percentage of orders without mistakes or discrepancies. This metric reflects the effectiveness of inventory management systems, picking processes, and overall operational accuracy.

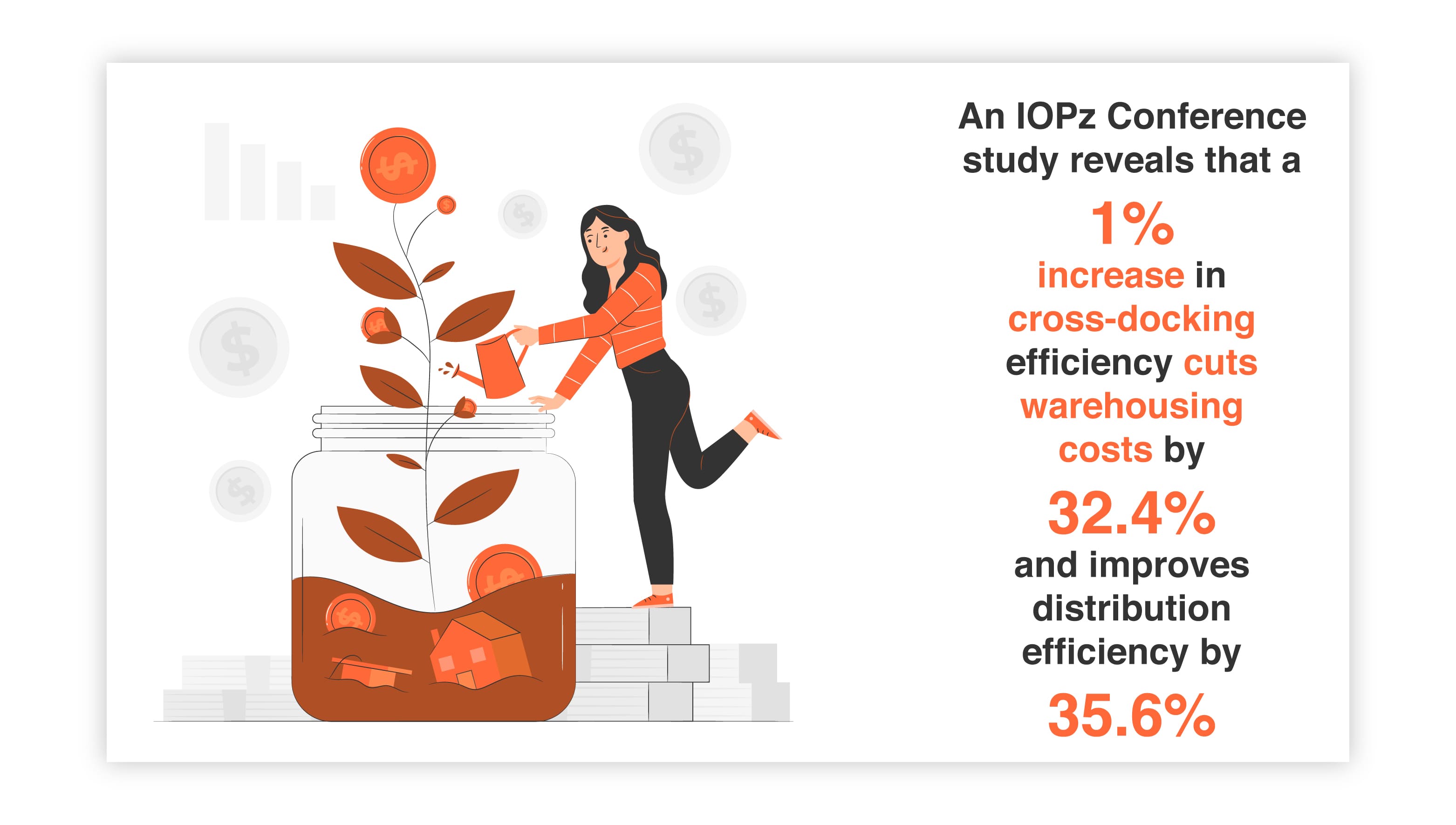

Efficiency should always be a priority when monitoring KPIs. One IOP Conference study shows that a 1% improvement in cross-docking efficiency reduces 32.4% warehousing cost and improves 35.6% distribution efficiency.

Delivery on time is an essential measure of success. It shows how many orders are delivered within the agreed time.

It directly impacts customer satisfaction and loyalty while indicating how well cross-docking operations meet customer demands.

Cross-docking benefits the environment by reducing the need for warehouse storage, minimizing product touches, and optimizing transportation. This leads to decreased energy consumption, lower emissions, and a more sustainable supply chain.

The primary drawback of implementing cross-docking is the high upfront cost.

The potential risks and disadvantages of cross-docking include unpredictable customer demand, IT system support, changing business dynamics, supplier and carrier reliability, facility design, shelf-life concerns, and ROI considerations.

These challenges require appropriate strategies and systems to overcome for successful implementation.

Specific industries or sectors that can benefit the most from cross-docking include retail, e-commerce, manufacturing, and distribution.

Cross-docking helps these industries optimize their supply chain operations, reduce costs, improve efficiency, and enhance customer satisfaction through faster order fulfillment.

To effectively manage inventory levels in a cross-docking system, companies can employ strategies such as real-time visibility of inventory, accurate demand forecasting, efficient coordination with suppliers and carriers, and implementing robust warehouse management systems for seamless tracking and organization.

Technology is essential for optimizing cross-docking. It helps with tracking, automating processes, and improving communication. It also aids in data analysis for evaluation and improvement.

Cross docking is an essential strategy for managing supply chains and benefits businesses. It reduces storage space, improves efficiency, lowers costs, and speeds up delivery times. But there are challenges like uncertain customer demand and the need for dependable IT systems and suppliers.

Companies can optimize their cross-docking operations by implementing best practices like using reliable warehouse management systems and optimizing warehouse layout.

Key performance indicators can be used to evaluate the overall performance of cross-docking. In general, cross-docking has many benefits. However, it needs careful planning and the right strategies and systems.

The supply chain is a term used to describe all the components required to transport goods from beginning to end, from production to the end...

A smart warehouse is a large building where raw materials and other consumer goods are stored using machines, computers, comprehensive software, and...

Direct-to-consumer (DTC) fulfillment is a strategy that helps brands sell and deliver their products directly to customers more efficiently while...