Cold Chain Logistics: Management Challenges & Solutions

The supply chain is a term used to describe all the components required to transport goods from beginning to end, from production to the end...

9 min read

BUKU Marketing

:

Jun 14, 2023 1:00:00 PM

BUKU Marketing

:

Jun 14, 2023 1:00:00 PM

Businesses are required to make many decisions every day. It's so essential to the success of an organization that they developed a moniker for it: decision-makers. One of the most critical decisions that eCommerce businesses must make is balancing their inventory with demand.

Table of Contents

1. Types Of Demand Forecasting

1(a). Quantitative Demand Forecasting

1(b). Qualitative Demand Forecasting

4. Technology in Demand Forecasting

7. Best Practices for Demand Forecasting

This can be a real challenge, and failing that challenge can mean substantial monetary losses for retail companies. For instance, a study conducted in 2015 of the leading 2000 companies in the U.S. and Europe found an estimated $187.5 billion and $820 billion, respectively, invested in unnecessary inventory. That money is tied up in extra inventory, which is taking up storage space, using production time, and eating up profits.

One of the best ways to avoid a situation like this is through demand forecasting, which is defined as a technique that organizations can use to estimate future consumer demand. This can be achieved through several methods, including qualitative and quantitative.

This post will define demand forecasting, explain why it is important, and delve into the details of those differing methods. Plus, we will offer some helpful tips businesses can use to get it right.

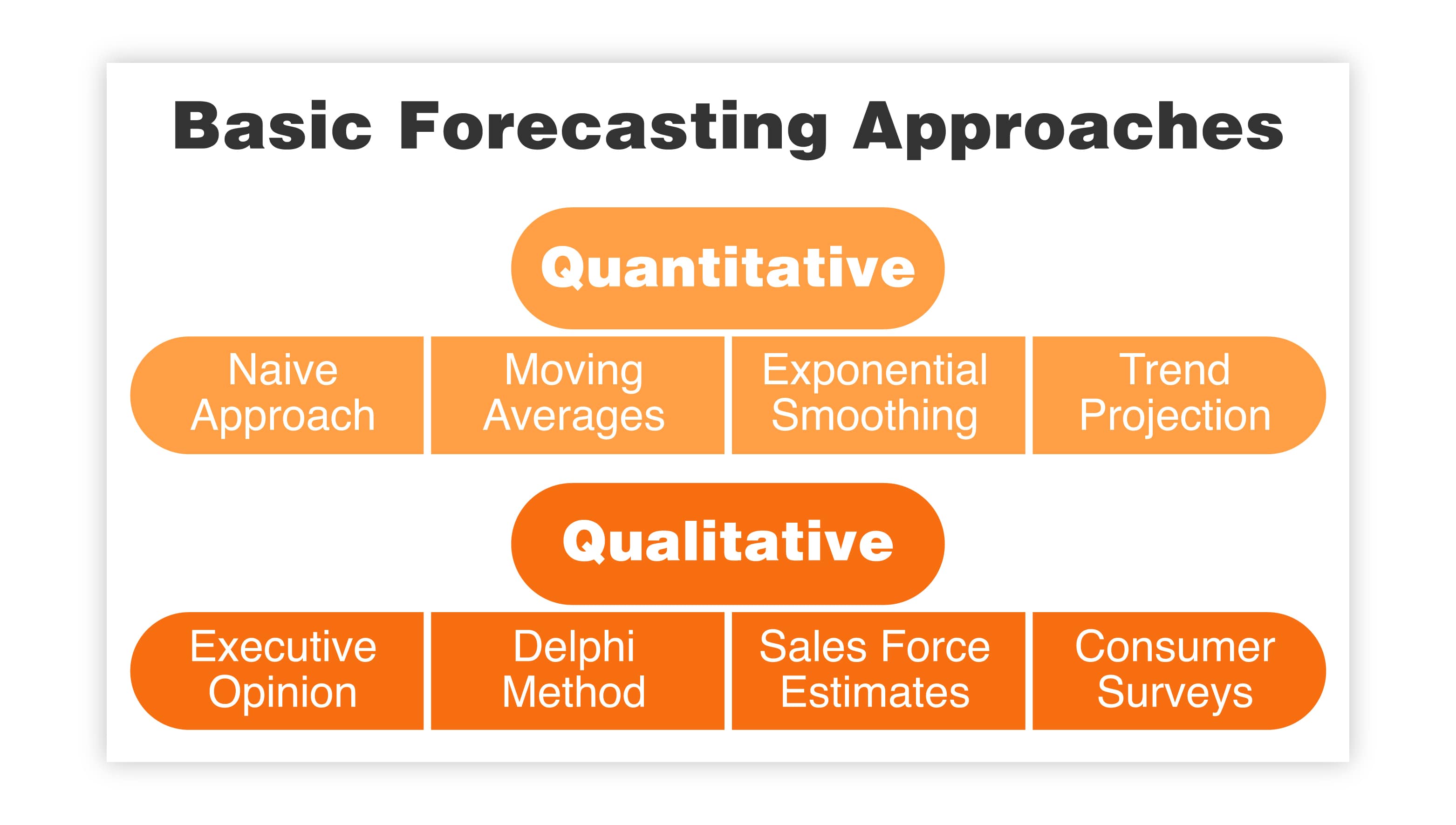

There are two basic types of demand forecasting: quantitative and qualitative. Each has its role to play in the way that companies can optimize their production and inventory levels, and each has its pros and cons.

Let’s look closer at the differences between the two:

Quantitative is a term that relates to hard data and numbers. When companies use quantitative demand forecasting, they rely on the exact numbers obtained through data analysis over a particular period.

This type of demand forecasting uses hard data and statistical analysis to make accurate predictions based on past experiences. Because it uses real data points in its predictions, quantitative forecasting is very accurate and tends to be more objective.

However, it can make it harder to account for unexpected circumstances that are bound to arise eventually. Relying on hard data is great in many ways, but there is little flexibility in that type of system to account for sudden fluctuations and unforeseen events. Plus, any system that relies on numerical data is vulnerable to errors.

Qualitative forecasting is often necessary when companies don’t have hard data to lean on, which would be the case for a newly formed business in its first year or when forecasting demand for a new product line. Without historical data to use in predictions, qualitative forecasting instead turns to market research, expert opinions, and comparative analysis.

This type of demand forecasting can better account for a market's unpredictability. It can be easier to understand and more accessible than quantitative because it relies on opinion, ideas, and emotion rather than hard numbers.

However, any system that relies on the opinion of humans, whether experts or consumers, is vulnerable to potential bias. Qualitative forecasting also lacks some of the details that historical data can provide.

Historical data is one of the most useful pieces of information companies have access to, especially regarding demand forecasting.

Even without trying to, businesses use historical data to influence decisions. One experience influences another, and businesses use historical information to predict future outcomes.

Regarding demand forecasting, historical data can provide valuable insights into the cause-and-effect relationship of the supply chain, inventory management, and market demand. Manufacturers must carefully balance these three components to be the most productive, efficient, and profitable – while ensuring that customers are satisfied.

Even with its benefits, historical analysis is not foolproof. There is no surefire way to predict the future, and situations can change overnight. But, if historical data exists, using it effectively can provide an idea of what to expect if circumstances remain the same.

One tool that companies use to analyze historical data is called “regression analysis.” Regression analysis is a statistical technique to find relationships between independent and dependent variables.

An example would be finding the relationship between interest rates and sales. Being able to plot out the way one variable relates to another can help companies predict future performance.

But, like anything, regression analysis has its drawbacks. For one, determining how two factors relate does not automatically mean one is affecting the other. Instead of pointing out a clear cause and effect, historical and regression analysis make it easier to spot patterns and use those patterns to predict future correlations.

Market research is a technique that allows companies insight into the consumers themselves – one of the most important components of demand forecasting. Consumers play a huge role in determining the strength of the market and how it changes over time, whether because of seasonal demand, location, or outside factors.

Because consumers represent the end of the line for retailers, their insights are invaluable. Businesses can use market research and historical analysis in demand forecasting to better spot trends and predict future sales.

Market research takes a few different approaches, including:

The consumer survey method involves direct interaction between consumers and companies, typically using direct interviews and questions. This allows businesses direct access to rapidly changing consumer opinions, knowledge about buying habits and expectations, and a better ability to predict future consumer behavior.

Trend forecasting considers the entirety of the consumer market and its shifting opinions. Trend forecasting uses historical data and consumer behavior analysis and keeps a watchful eye on the impact of cultural shifts and economic and environmental factors on consumer buying habits. Trend forecasting can look at the big picture over a long period, narrow its view to a shorter period, or zero in on a specific timeframe.

Competitor monitoring is something every business does, but it is also useful regarding demand forecasting. Typically, competitor monitoring compares a business’s market performance to other companies. But in terms of demand forecasting, it can be used to make better decisions.

Competitive Intelligence is a term used to describe useful and relevant information gathered during competitor monitoring. That information can help businesses understand competitors' motivations, strengths, and weaknesses, products, and services, and more. Businesses can use that information to make predictions about their performance.

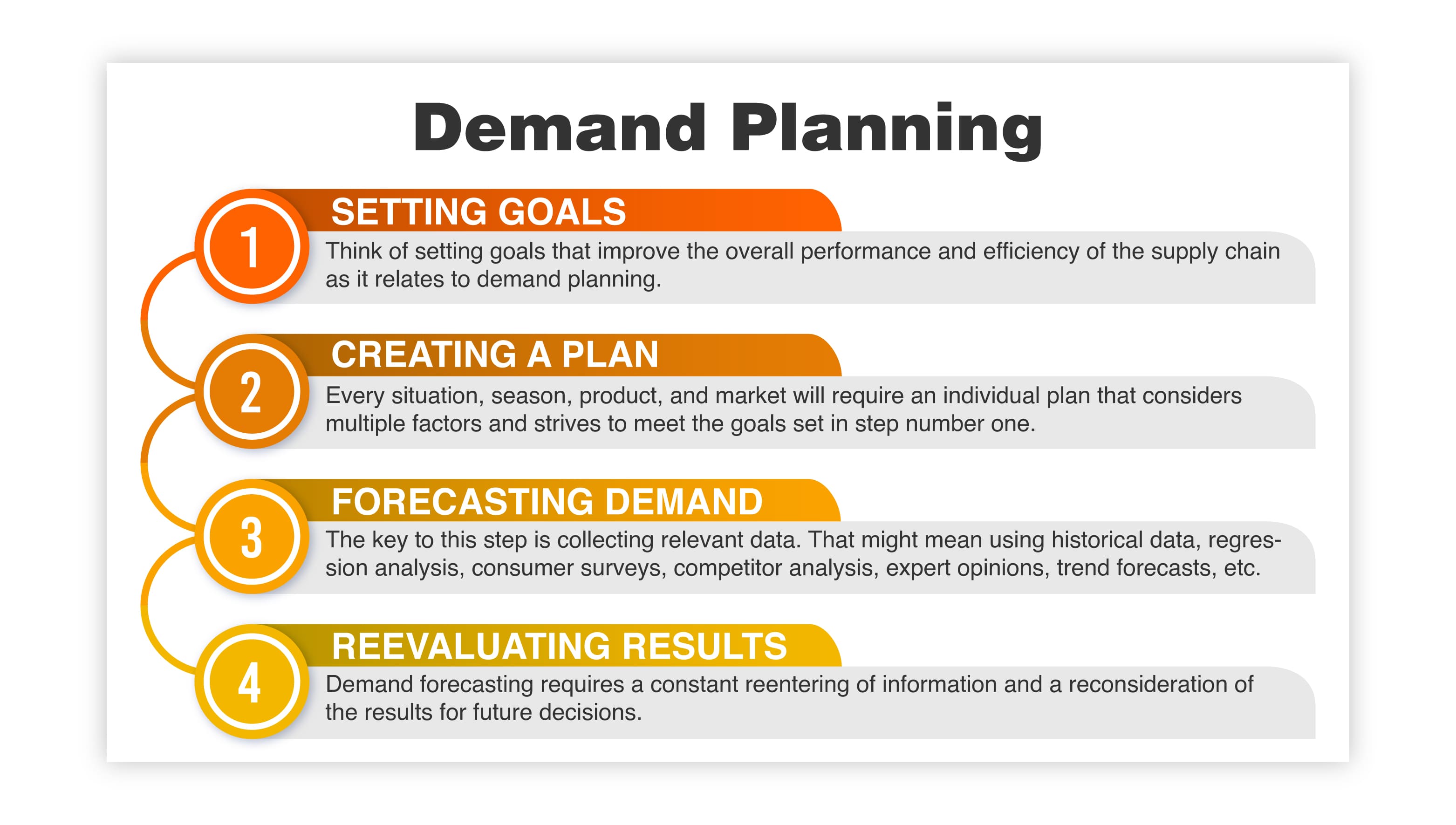

Demand planning is the process businesses use to make informed production decisions, prevent stockouts and overstocks, and prepare for unexpected disruptions in the supply chain. Planning efficiently is key to managing inventory levels and meeting consumer demands streamlined and profitably.

Demand forecasting is one step on the bigger ladder of demand planning, or in other terms, it’s a tool that makes demand planning more effective and successful. It involves steps that can help companies make the best decisions regarding their supply chain and sales and operations (S&OP) process.

We’ve outlined those steps below:

Think of setting goals that improve the overall performance and efficiency of the supply chain as it relates to demand planning. Maybe that means improving inventory levels, eliminating stockouts, or cutting expenses. Or maybe it means taking advantage of seasonal fluctuations to increase sales and revenue and using demand forecasting to ensure the most in-demand products are in sufficient stock.

Demand planning won’t work efficiently without a proper plan in place. Every situation, season, product, and market will require an individual plan that considers multiple factors and strives to meet the goals set in step number one. Try to think of those goals as problems that need solutions and devise a plan to solve them.

Use the most effective and logical method to forecast future demand or employ several methods. The key to this step is collecting relevant data. That might mean using historical data, regression analysis, consumer surveys, competitor analysis, expert opinions, trend forecasts, etc.

Demand forecasting aims to use statistical analysis to determine the most likely outcome based on all the factors. This will require companies to collaborate with manufacturers and partners, distributors, and customers to gather the most relevant information and make informed decisions.

No plan is complete until its results have been reevaluated, measured, and assessed. Demand forecasting requires a constant reentering of information and a reconsideration of the results for future decisions.

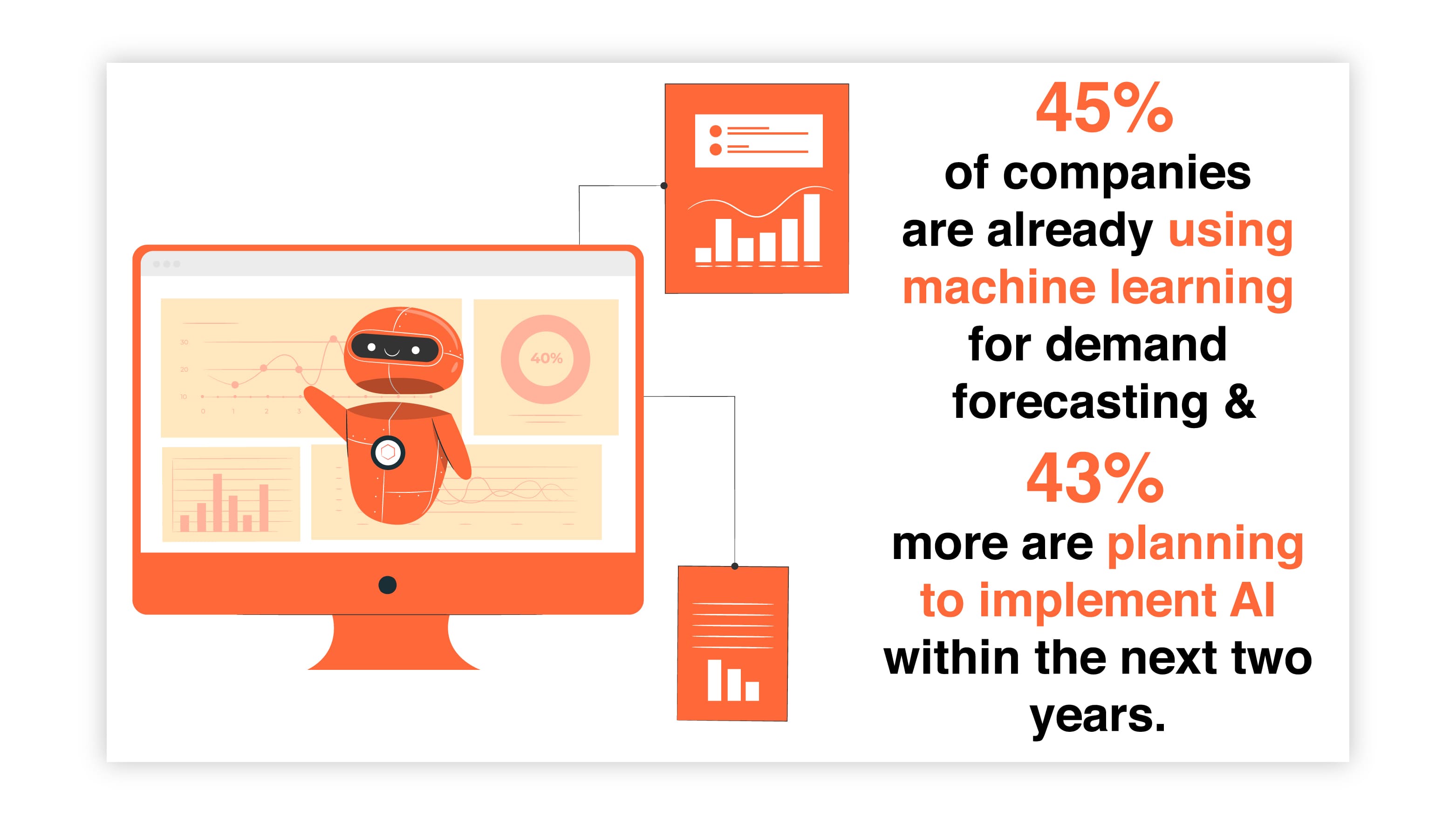

Technology has slowly crept its way into almost every facet of the business, including the eCommerce and retail sectors. Regarding demand forecasting, advancements in technology are proving extremely useful. AI and machine learning algorithms make data analysis and decision-making easier and more accurate.

Although the use of technology in demand forecasting is still new to many companies, its adoption is growing steadily. According to one study, 45% of companies already use machine learning for demand forecasting, and 43% plan to implement AI-powered technologies within the next two years.

Compare that to a survey conducted back in 2020, which found that only 9% of respondents were using ML in their daily demand forecasting activities, and it’s easy to see how quickly this technology is growing in its use and applications around the world.

Machine learning relies on algorithms to interpret and analyze data ever-evolvingly. This means that ML forecasting models take in data, recognize patterns, make predictions, and adapt based on the information. In essence, ML replaces the role of humans in the process, making better and more accurate predictions with fewer opportunities for error.

A study conducted by McKinsey Digital found that demand forecasting backed by AI can lead to a 30-50% reduction in errors in supply chain performance. The result was a 65% decrease in lost sales due to stockouts and a cost reduction of 10-40% for things like warehousing expenditures. That all adds up to an impact of between $1.2 trillion and $2 trillion for supply chain planning.

New technologies don’t always lead to better results, especially if those implementing them aren’t looking out for the common pitfalls. For example, AI-powered predictive analysis is only as good as the data it’s given. Without all the relevant information, AI is susceptible to error. This can be extra challenging for companies or product lines that lack historical data.

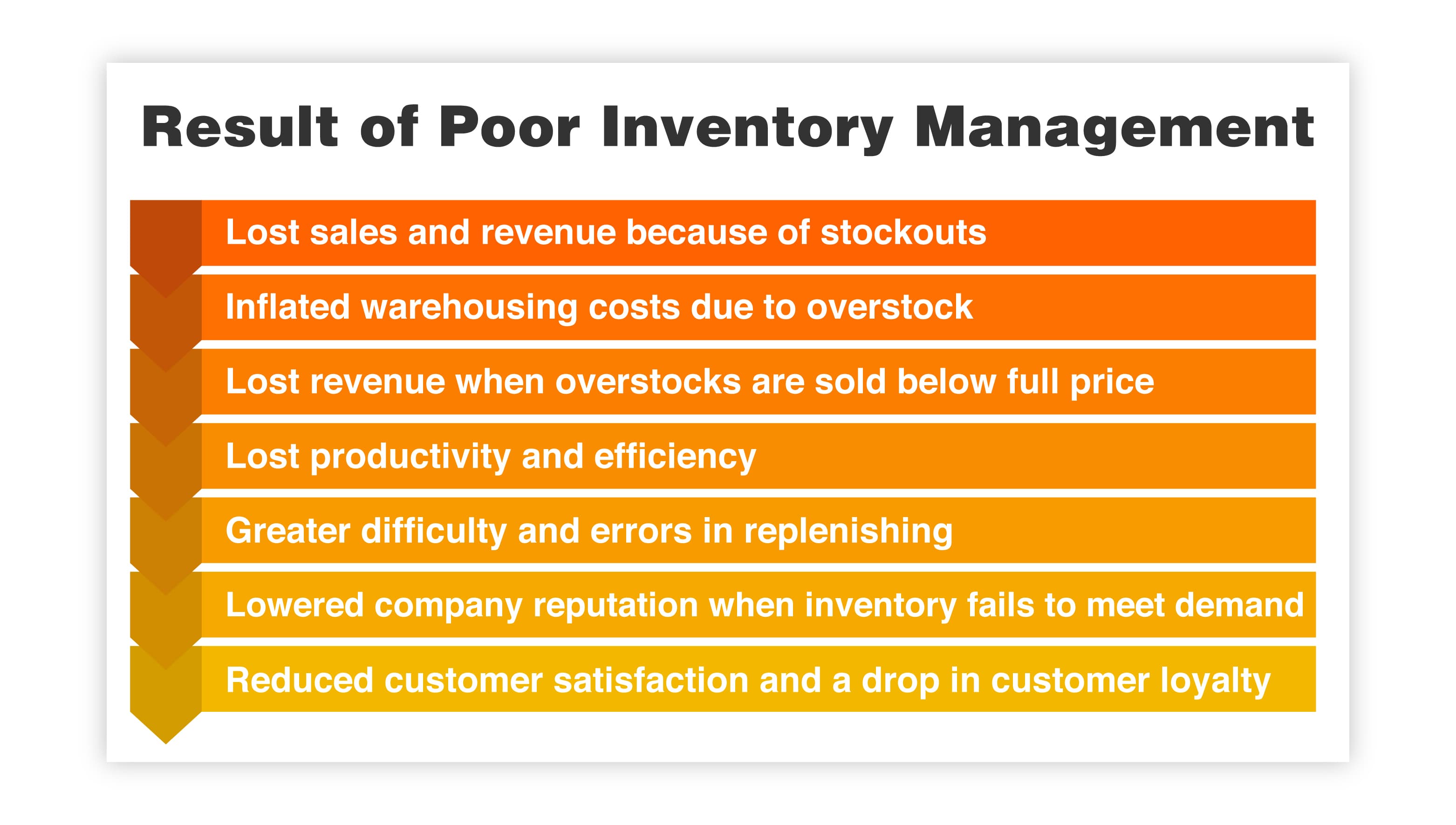

One of the most important tasks retail businesses handle daily is inventory management. And far from just requiring a running tally of what's in stock, inventory management involves multiple moving parts and targets that must be carefully balanced to remain successful. If one arm of the machine stops working or is out of sync with the others, disaster can follow.

Poor inventory management can lead to:

The good news is that demand forecasting can make inventory management easier. Knowing what to expect in terms of demand means easier and more efficient planning of replenishment schedules and the supply chain. The result is a better balance between what exists and what is needed.

Demand forecasting helps companies make better decisions, which results in better inventory management. And improved inventory management processes influence the effectiveness of future demand forecasting. It’s a never-ending circle of cause and effect. For retailers, the payoff of that cycle is reduced costs, better profitability, greater efficiency, and happier customers.

Inventory management is one area where technological advancements can make a significant difference for companies. Inventory management is a complex beast with lots of rapidly changing data. Using digital tools for inventory tracking and replenishment, implementing ML and AI in demand forecasting, and upgrading systems to meet rapidly changing needs will only benefit companies down the road.

All businesses face risk. Mitigating that risk and coming out the other side while maintaining profitability is the key to remaining competitive. Demand forecasting is one of the most effective ways for companies to weather the common risks of doing business.

As it relates to the supply chain, those risks are things like supply chain disruptions – something that happened in unprecedented numbers post-Covid. Other risks are changes in consumer preferences and buying behaviors, economic and environmental factors, and other external factors that companies have no control over.

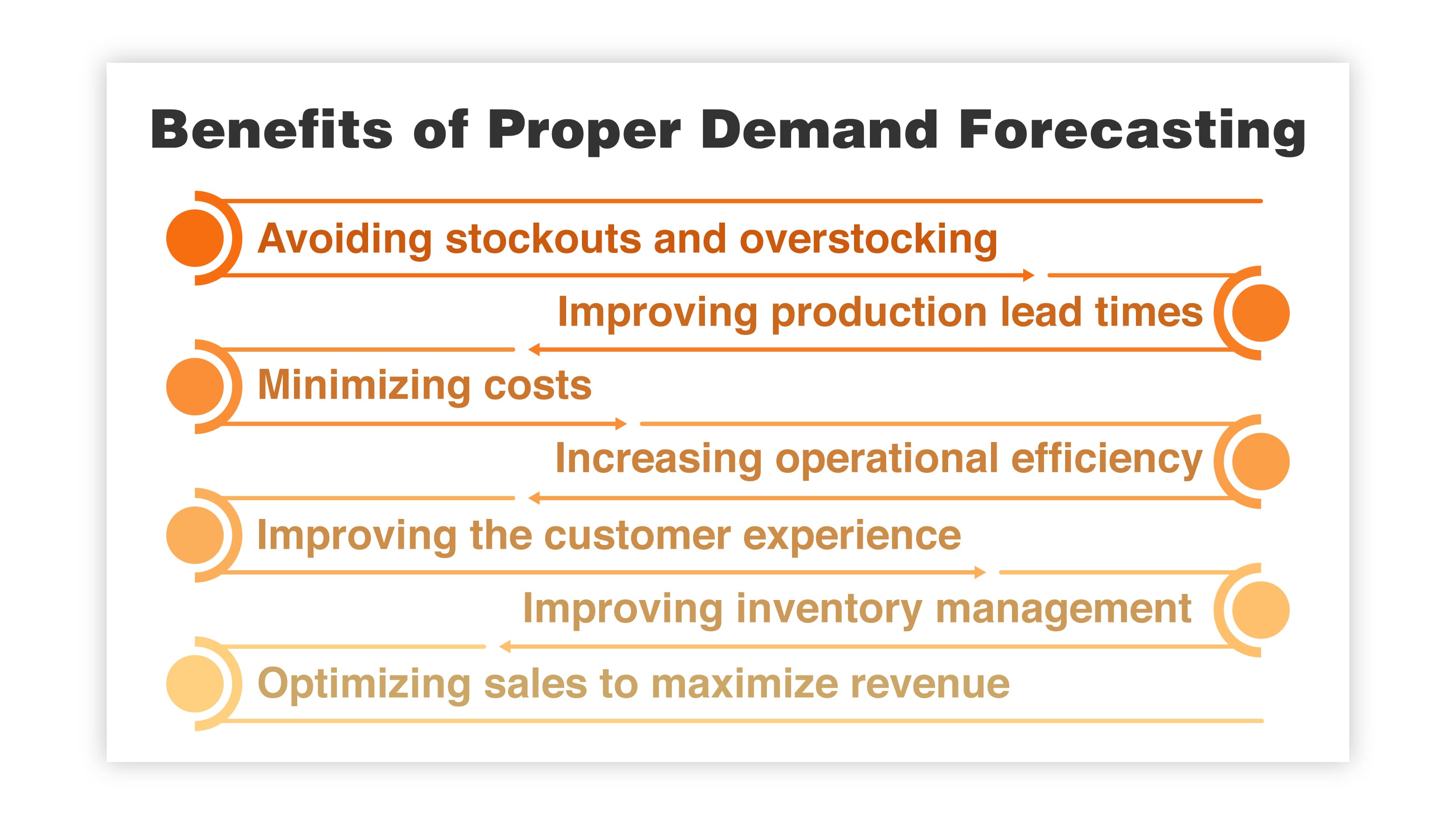

Accurate demand forecasting helps companies survive circumstances like these by optimizing everything on the other end as much as possible. Every piece of the puzzle comes together to provide as much cushion as possible for businesses when those unavoidable risks come knocking. The benefits of demand forecasting like those listed below help provide that cushion.

All these things enable businesses to survive uncertainty and plan more effectively. And they can all be achieved through accurate demand forecasting.

Demand forecasting is useful for companies for so many reasons. But it’s one of those things that can do more harm than good if not done correctly. The Institute of Business Forecasting estimates that the average one-year forecast for consumer products companies has a margin of error of as high as 20%, which can lead to annual losses as high as $225 million.

Any time a decision is made using poor, inaccurate, or incomplete data – the outcome is not likely to be positive. Here are some actionable tips that businesses can use to improve their demand forecasting practices and get better results.

Take advantage of technology

The best piece of advice we can give for more accurate demand forecasting is to leverage the technology available. Progress is there for a reason. Take advantage and put the right tech pieces in place for better results.

Identify anomalies

Anomalies happen when unexpected shifts in demand occur. For demand forecasters, anomalies should be a giant red flag pointing to important information that requires attention. Understanding what factors may have contributed to the sudden shift can help businesses recognize that scenario in the future.

Recognizing correlations

A correlation between anomalous demand and demand causal factors is another way to predict future shifts. When a causal factor directly affects demand, whether positive or negative, recognizing and understanding that correlation can help businesses plan for it the next time.

Leverage data – Internal and External

Data from within the business itself drives demand forecasting, but so does external data. Make sure to leverage data from all sources and as many different sources as possible for the best outcome. More data is always better, and external data is more unpredictable and unplanned, which can be more useful in historical and predictive analysis.

Hone your data model

Taking advantage of AI and ML can help companies make better use of the data. But the outcome won't be optimized unless the ML model fits the dataset effectively. Learn how to tweak your data model for the best outcome based on what kinds of data you’re feeding it and what you expect the system to do with that data.

Success in any business requires having the right product at the right time. If you fail to meet the demand of consumers, you will end up with unhappy customers and lose out on valuable sales. If you overreach and spend too much on operations or production, you will end up wasting resources and money, which again means a loss in profitability.

Doing any job correctly is easier if you use the right tools, and that includes decision-making. For eCommerce companies, demand forecasting is the tool that helps them plan for future business and optimize supply chain operations as efficiently as possible. It's like a periscope into the future – the future of the market, consumer behavior, product demand, and outside factors.

Demand forecasting itself includes several methods that companies can use to generate a statistical analysis and thereby predict future demand. Whether you use quantitative or qualitative methods, each comes with its own pros and cons, and each approach should be applied under the right circumstances.

Getting it right every time is a challenge, and nobody is saying otherwise. But if you put the right tools in place and make use of the best technology, you will get better results and have greater success across the board.

The supply chain is a term used to describe all the components required to transport goods from beginning to end, from production to the end...

A smart warehouse is a large building where raw materials and other consumer goods are stored using machines, computers, comprehensive software, and...

Direct-to-consumer (DTC) fulfillment is a strategy that helps brands sell and deliver their products directly to customers more efficiently while...