Cold Chain Logistics: Management Challenges & Solutions

The supply chain is a term used to describe all the components required to transport goods from beginning to end, from production to the end...

10 min read

BUKU Marketing

:

Apr 12, 2023 1:00:00 PM

BUKU Marketing

:

Apr 12, 2023 1:00:00 PM

E-commerce businesses use various tools to help them succeed. One of the most useful and fastest growing in terms of popularity is using a third-party logistics service or fulfillment center to help manage supply chain operations.

Table of Contents

1. Why 3PL Inventory Management Is Important?

2. Best Tips To Get Control Over Inventory Management

3. Benefits Of Efficient Inventory Management In 3PL

4. Ensure Your Inventory Is Accurate

5. Implement An Order Picking System

6. Using Tech In 3PLs And Fulfillment Centers

7. The Importance Of Communication In 3PL

8. Real-Time Inventory Tracking And Staying Organized

9. Final Thoughts On 3PL Inventory Management

The global logistics market had an estimated value of $8.4 trillion U.S. dollars in 2021 and is expected to exceed $13.7 trillion by 2027. Changes and disruptions in the supply chain after the Covid-19 pandemic, coupled with the inclusion of ever-advancing technology, have made 3PLs incredibly valuable for businesses of all kinds, eCommerce included.

3PLs manage various supply chain processes for businesses, including warehousing, shipping and receiving, and managing inventory. As the popularity and complexity of these services have grown, 3PL inventory management processes have also had to adapt .

Managing inventory is an important part of running a successful 3PL service and is vital for the success of that company’s clients.

This article will explain what inventory management means in a third-party logistics center and how optimizing the processes and systems used to complete this vital task can benefit those businesses. We will also offer some tips on exactly how 3PLs can accomplish this.

Managing inventory properly is one of the most important tasks for a retail business. Companies need to balance the number of products in stock and the number of products sold to avoid stockouts and tying up precious capital in excess inventory.

Maintaining accurate inventory counts helps businesses keep track of what they have and what they need. Careful organization of that inventory helps businesses keep customers happy during the ordering, shipping, and delivery processes.

And it helps businesses plan for seasonal fluctuations, aids in easier growth and saves them time and money. 3PL inventory management is important to third-party logistics centers because it’s important to the businesses that pay for their services.

One of the biggest advantages for businesses that properly manage their inventory is the ability to balance inventory levels against sales. If a product sells extremely well, then a business needs to keep an ample inventory of that product to meet demand.

Suppose a business doesn’t have an accurate inventory count. In that case, they risk being out of stock on the exact product they need, leaving customers unhappy and sacrificing precious revenue.

A 3PL that helps businesses track inventory levels in real-time assists businesses in planning and strategy and helps eliminate costly snags in the supply chain.

Inventory is expensive, especially when businesses need to buy in bulk to meet demand. Spending tons of capital on inventory is a huge expenditure for retail businesses.

Without an accurate tally of the inventory on hand and the ability to track the movement of inventory through the supply chain, businesses are left unable to plan their inventory expenditures appropriately and risk spending capital on products that do nothing more than take up space in the warehouse.

3PLs who take advantage of technology can provide customers with real-time tracking, data, and analytics that can prove invaluable. Transparency gives customers a clear understanding of the operability and efficiency of their supply chain, plus the ability to spot problems quickly.

Inventory management provides insights that can help businesses spot trends and react accordingly. And because of the way technology integrates numerous steps in the supply chain, customers can track their orders and get up-to-date delivery information.

Manual processes are slow, time-consuming, and susceptible to human error. Efficient and modern inventory management systems eliminate the need for redundant manual processes and make it less likely that employee mistakes will skew inventory counts – an error that can cost businesses more than time and money but customers and their reputation as well.

Businesses that use multiple suppliers have an advantage because they can navigate supply chain disruptions, which has become more common in the post-covid economy.

Even with the disruptions caused by the pandemic lessening, other unpredictable factors can quickly arise and wreak havoc on a business's ability to get the necessary products and materials.

Bloomberg recently listed the war in Ukraine, fears of a recession, extreme weather events, and even politics as potential supply-chain interrupters heading into 2023.

When 3PLs use efficient and centralized inventory management systems, businesses can make smarter decisions regarding their suppliers.

They can easily spot outliers that don’t meet expectations and manage multiple suppliers at once, giving them ample wiggle room when one supply route collapses unexpectedly.

So, now that we know 3PL inventory management is vital for all partners' success, how can third-party logistics providers improve their processes? It starts with implementing the newest technology.

Warehouse Management Systems, or WMSs, can help 3PLs by automating and integrating many steps to maintain accurate inventory management processes. But there are even simple things that 3PLs should have in place to improve their performance when managing inventory and helping their customers succeed.

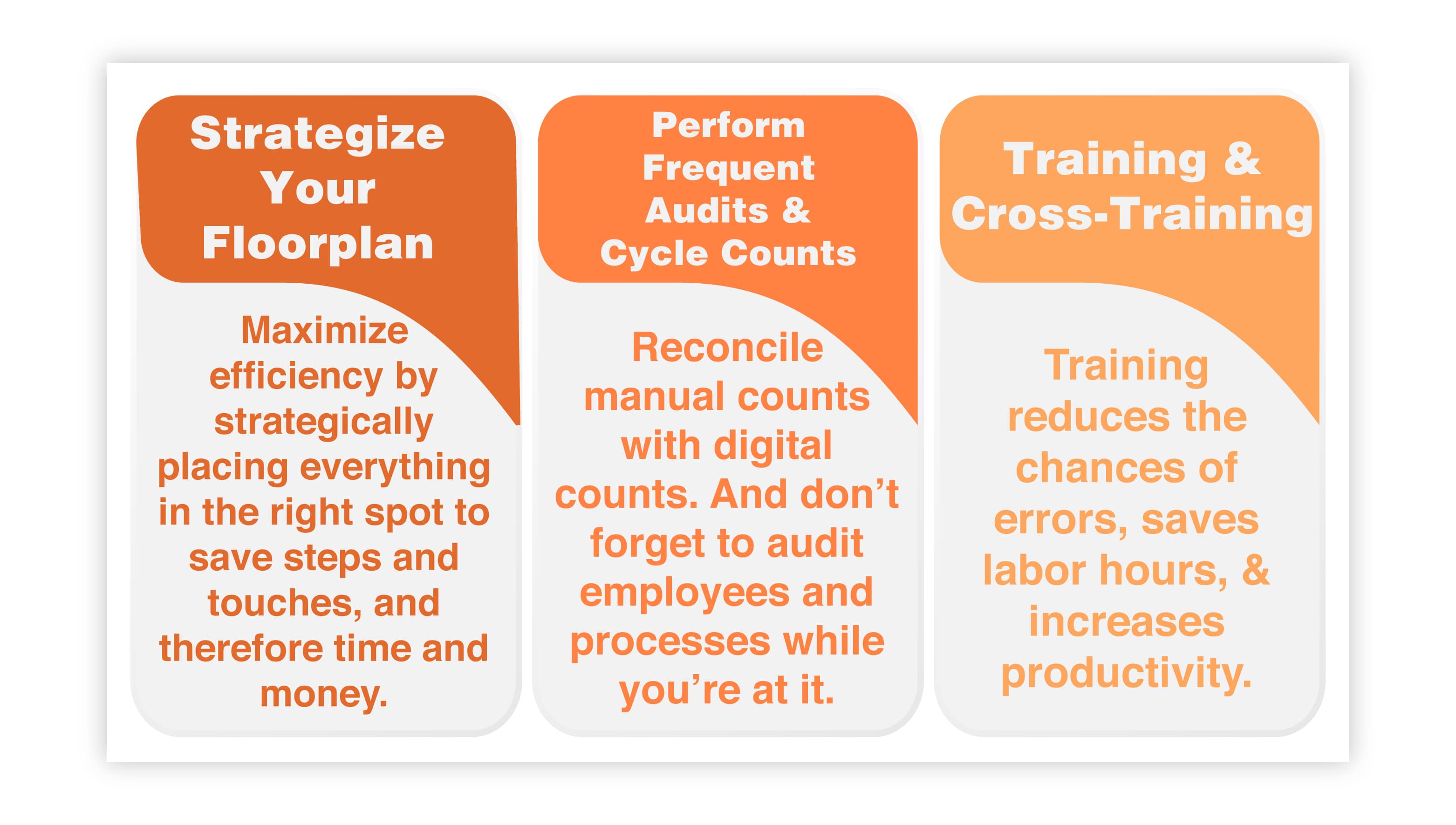

How you organize and set up your warehousing space will greatly impact how efficient your employees are when moving around and filling orders. Maximize efficiency by strategically placing everything in the right spot to save steps and touches, time and money.

Even automated systems need supervision and maintenance. The best way to maintain accurate inventory counts is by conducting regular audits and counts of that inventory. Reconcile manual counts with digital counts.

And don’t forget to audit employees and processes while you’re at it. That way, you can ensure that workers are following established procedures.

3PLs can improve processes across the board, including inventory management, by ensuring that the employees tasked with running the warehouse are properly trained in the first place.

Training reduces the chances of errors, saves labor hours, and increases productivity.

Cross-training employees to perform multiple tasks can also help 3PLs manage productivity by providing the ability to cover missed shifts and boost the morale of employees when they’re allowed to perform different tasks.

Inventory management directly affects the success or failure of a third-party logistics service or fulfillment center. If your customers aren’t happy with your performance, they won’t stick around.

Businesses choose to use a 3PL to make their processes faster and easier, and when you don’t hold up your end of the bargain, success will be hard to maintain. Here are some benefits 3PLs gain with improved inventory management processes.

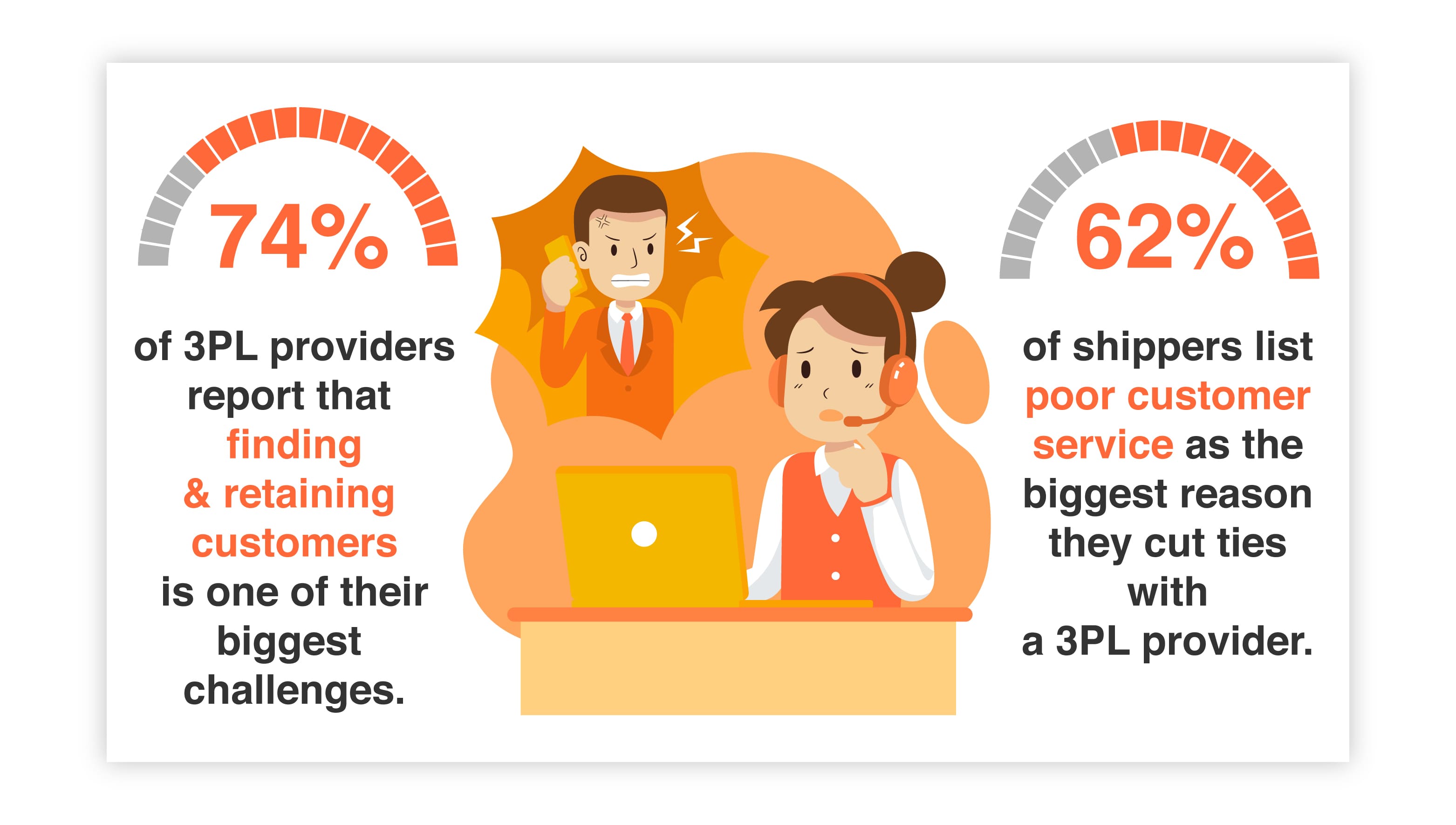

A recent study found that 74% of 3PL providers report that finding and retaining customers is one of their biggest challenges. Another statistic shows that 62% of shippers list poor customer service as the biggest reason they cut ties with a 3PL provider.

Being able to provide accurate inventory counts for those customers is a big part of the equation for keeping those customers happy.

Operational efficiency reduces the need for labor hours – it's just a fact. When employees are empowered to do their jobs faster and more successfully, there is less need for other employees to follow behind and correct mistakes.

Instead of hiring extra employees to boost productivity, focus on improving the performance and efficiency of your current workforce by giving them the tools and knowledge they need to get the job done right the first time.

Businesses have fluctuating needs – a fact that is especially true in the retail sector. Inventory demand changes seasonally, and not just a little bit. On top of that, businesses are looking for a partner that will make growth and scale easier, not harder.

Ensuring that operations are efficient, organized, and accurate will provide peace of mind to businesses that need fast and efficient adaptability from their 3PL.

Inventory management helps 3PLs plan how they use available warehouse space. Real-time insights allow better planning and layout of products and pallets on a warehouse floor, which improves efficiency, saves on labor costs, and reduces the time it takes to fulfill orders.

One of the biggest advantages for 3PLs who use advanced software technologies is the ability to track inventory as it moves through the warehouse in real-time. Customers can access detailed reports showing how much inventory they have on hand, which products are selling, and which are just sitting.

The essence of 3PL inventory management is maintaining the most cost-effective inventory levels while expediting logistics processes. For the system to work correctly, an accurate count is essential. If the count is off, everything else will fall apart.

3PLs who use the right tools and systems to manage inventory as it moves through the warehouse can provide customers with the information they need to succeed. That includes reducing the occurrence of stockouts, which stop retail businesses in their tracks.

It also prevents the scales from tipping in the other direction by helping businesses avoid spending huge chunks of capital on products that aren’t selling fast enough. Overstocking is also detrimental to the 3PL provider because it takes up valuable space on the warehouse floor.

Besides the benefits for customers, 3PLs have a lot to gain from implementing systems that provide accurate inventory counts. Increased efficiency on the warehouse floor during every step of the process is a big one, as is the ability to save money by minimizing operational overhead.

Better processes, increased productivity, improved customer satisfaction, and reduced spending are all within reach when 3PLs focus on accurate inventory management.

3PL inventory management is an evolving process that leans heavily on the needs and wants of its customers.

And what do customers want? Better efficiency, improved performance, and happier customers on their end. That means putting the right systems and structure in place to accommodate those needs.

Here are some ways 3PLs can get the job of inventory management done more efficiently.

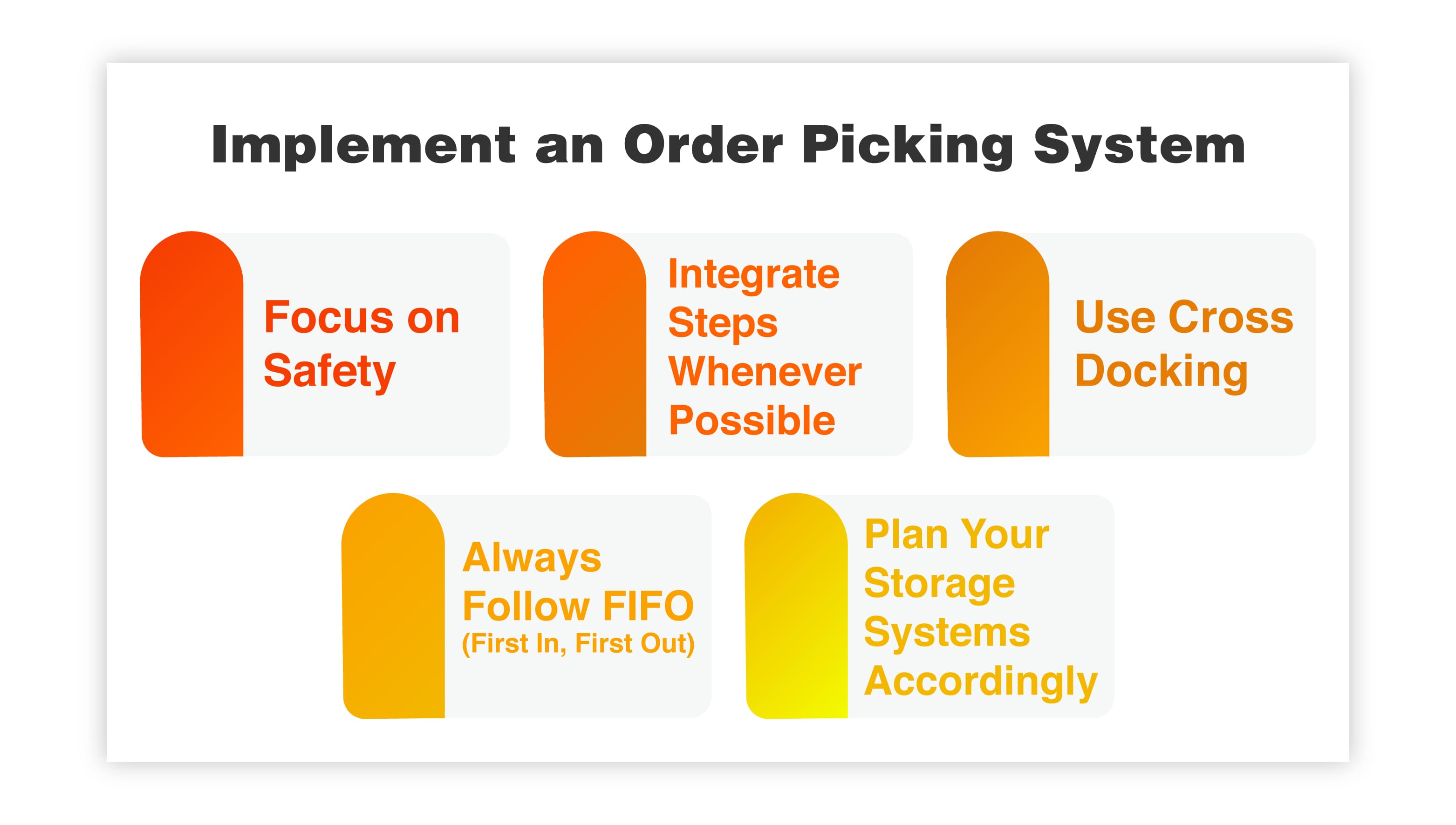

There should always be a “safety-first” attitude on the warehouse floor. Proper training, floor layout, maintenance, and safety procedures are essential and directly affect a 3PLs ability to manage inventory levels effectively.

Remember that everything is interconnected, and accidents can lead to profit and productivity loss, which means less money to invest in inventory management technology.

The use of technology and automation has changed how warehouses operate. One of the ways that 3PLs can improve productivity is by integrating individual steps in the fulfillment process. It’s all about saving time and steps, which you can reallocate to other tasks.

For example, consider consolidating the packing and shipping areas into one station to reduce the need to move inventory between the two.

Cross-docking is a process that eliminates a time-consuming step in the logistics system. Suppose you receive a shipment of goods intended for immediate delivery to a customer.

In that case, you can use a cross-docking station located close to the loading dock to store those goods in preparation for transfer temporarily.

Doing so eliminates the need for those products to travel to a storage area, only to be retrieved shortly after by an employee for delivery.

FIFO stands for “first in, first out,” and it’s a common motto across the retail industry. 3PLs should always follow FIFO when storing received shipments and when picking orders.

This protects customers' investments by ensuring that new products are cycled to the back of the storage area and older products are picked for delivery first.

There are many storage solutions that 3PLs can store goods in a warehouse, and just as many they can use for shipment and delivery.

Instead of spreading resources out by trying to configure systems to meet every individual storage, shipment, and delivery need, focus on a few that offer the most flexibility and stability to reduce costs and limit damages.

There have been numerous advancements in the way that 3PLs operate, and that includes automation and technology that can improve efficiency, automate processes, and create a centralized system.

It’s expected that no less than 50,000 warehouses will rely on automation and robotics by 2025. Here are a few examples of how technology can help 3PLs improve their inventory management systems.

WMS – A good WMS, or warehouse management system, has become virtually essential for 3PLs. A WMS uses software to track everything that enters and exits the warehouse or fulfillment center.

These systems are designed to help 3PLs manage every step of the process, including receiving, picking, packing, shipping, and delivery.

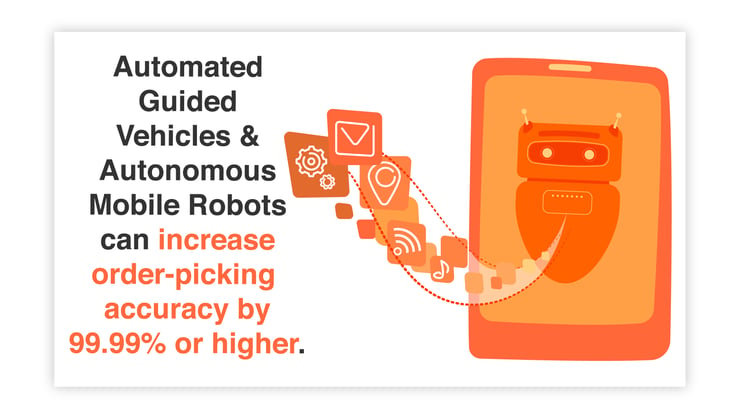

AGVs/AMRs – Also known as an “automated guided vehicle,” an AGV is an autonomous vehicle that moves goods through a warehouse – without the need for a driver. AMR stands for “autonomous mobile robots.”

Although these are fairly new technologies, many 3PLs use them as a better and more cost-effective way to maneuver inventory around the warehouse floor.

Want proof? Studies show that using AGVs and AMRs can increase order-picking accuracy by 99.99% - or higher.

Mobile and Wearable Technology – Many 3PLs now equip employees with mobile devices that help them perform job tasks faster and more efficiently, like scanners and tablets.

These wireless devices can save time by allowing employees to save steps on the warehouse floor and reduce errors in the picking process by 67% compared with manual processes.

Software Solutions – There are numerous software solutions that 3PLs and fulfillment centers can use to improve their processes, save time and money, and improve customer satisfaction rates.

For example, BUKU’s app Intellirate provides 3PLs with access to real-time analytics and shipping solutions easily integrated with existing systems. Users get access to a live P&L dashboard to see dynamic shipping rates, get accurate shipping dates, print labels, and track deliveries.

IntelliRate helps 3PLs connect to a network of global carriers, which can mitigate risk by providing options for every situation.

With this solution, businesses can increase their efficiency and make better decisions with access to valuable data and analytics. BUKU works with fulfillment centers and brands alike to improve the customer shipping experience.

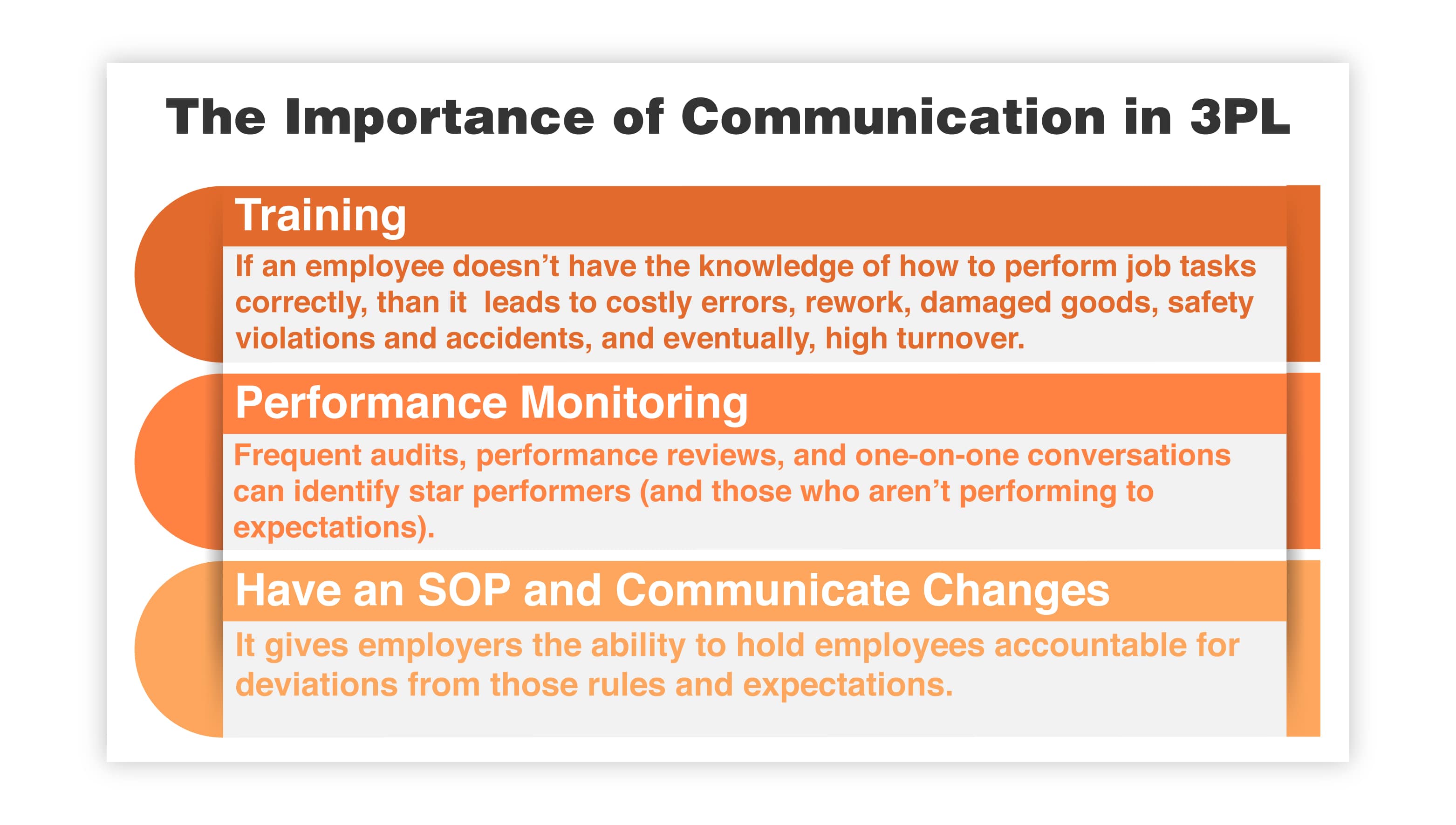

Training and communication are vital components for any successful business process, including 3PL inventory management.

Logistics and fulfillment centers handle huge amounts of goods and materials daily, and accurate execution of processes can make the difference between a happy customer and a disgruntled former customer.

Everything will move smoothly when communication lines are open between departments, supervisors, and employers.

Even upper management and lower-level workers. However, when communication is hampered, either by a lack of training or oversight, or missing procedures, costly mistakes will follow.

Good communication starts the first day an employee steps onto the job. If an employee doesn’t understand their responsibilities or know how to perform job tasks correctly, they are left to fill in the blanks themselves.

This leads to costly errors, rework, damaged goods, safety violations and accidents, and high turnover. Make sure that the training takes place both in the classroom and on the warehouse floor in real-time.

Training is an ongoing process that should never end. Employees deserve ongoing training and the ability to progress in their job roles. And they need frequent oversight to keep them motivated, as well as to correct mistakes – whether they're intentional or not.

Frequent audits, performance reviews, and one-on-one conversations can identify star performers (and those who aren’t performing to expectations).

An SOP, or "standard operating procedure," is essential for training and monitoring employees on the warehouse floor. Having one set of rules helps employees understand their responsibilities.

It also allows employers to hold employees accountable for deviations from those rules and expectations.

Advancements in technology and automated solutions have made 3PL inventory management faster, easier, and more accurate.

One of the biggest changes that 3PLs have seen comes in the form of real-time inventory tracking. There is no better tool that 3PLs can use for maintaining accurate inventory counts.

Real-time inventory tracking means more than just knowing what’s in your warehouse. It includes knowing what products you have on the warehouse floor, what products are on their way for receiving and out for delivery, where those products are located within the warehouse, and much more.

It includes detailed information that 3PLs can share with their customers to help both parties plan and navigate logistics.

Keeping an accurate count, in real-time, of what is present in a warehouse allows for better storage and warehouse layout planning. It helps you and your customers maintain accurate stock levels to match their sales volume, which helps balance stock between what is needed and what is not.

Organizing inventory in the warehouse is just as important for effective inventory management. It helps employees fill orders faster, saves steps, and reduces the number of times employees must touch a product – all of which saves time and money.

It also reduces the risk of errors and accidents, which can reduce productivity and result in damaged goods or injured employees.

3PLs are all about providing improved efficiency and easier logistics handling for retail businesses. For that to happen successfully, a focus on improving 3PL inventory management is a must.

Effective and efficient inventory management processes will help 3PLs reduce labor costs, improve operational processes, and increase productivity. Orders can be picked, packaged, and shipped faster and more accurately.

Planning and forecasting are easier. Staffing needs and labor costs are lower. Overhead costs are reduced, and those savings can be applied to other areas.

Improving inventory management goes beyond operational advantages, however. When 3PLs are organized, efficient, and prepared to meet the needs of their customers, they will have a better chance of building long-term relationships with those customers.

Maintaining a high customer retention percentage will help 3PLs save money on customer acquisition costs and marketing and increase the average lifetime value of each business they partner with.

The supply chain is a term used to describe all the components required to transport goods from beginning to end, from production to the end...

A smart warehouse is a large building where raw materials and other consumer goods are stored using machines, computers, comprehensive software, and...

Direct-to-consumer (DTC) fulfillment is a strategy that helps brands sell and deliver their products directly to customers more efficiently while...