Cold Chain Logistics: Management Challenges & Solutions

The supply chain is a term used to describe all the components required to transport goods from beginning to end, from production to the end...

12 min read

BUKU Marketing

:

Jan 18, 2023 1:00:00 PM

BUKU Marketing

:

Jan 18, 2023 1:00:00 PM

If you are already operating an eCommerce store that sells frozen foods, or are planning to start, you may have already learned a bit about the shipping process.

Table of Contents

1. What Are Some Challenges Of Shipping Cold Food?

2. What Is The Best Way To Ship Frozen Meat?

3. How To Ship Frozen Foods According To Shipping Carriers?

4. What Are Some Things To Keep In Mind When Shipping Frozen Foods?

5. How To Pack Frozen Food For Shipping?

6. What Are The Different Ways To Keep Food Cold?

7. What Are The Risks Of Shipping Frozen Foods?

8. How Much Does It Cost To Ship Frozen Food?

Managing shipping carriers, choosing packaging products, and finding the cheapest way to ship for small businesses are all crucial steps in creating a successful online retail venture.

However, if your eCommerce store deals with perishable items, then the complicated matter of shipping becomes an even more significant challenge. The world has embraced online shopping, spurred partly by the pandemic and helped along by technological advances.

However, figuring out how to ship frozen food and perishable items remains a mystery to many businesses. If you're planning to sell these kinds of products in your online store, you must learn the best techniques and methods for ensuring your customers don't receive spoiled, melted goods.

Otherwise, you could lose money, anger customers, and even risk legal repercussions.

If you're new to the eCommerce business or just looking for tips on how to ship frozen foods, this article is for you. We will outline the best ways to keep your food cold and your sales hot, so your customers are happy and well-fed.

Shipping products from one place to the other already requires planning. Choosing suitable packaging and cushion material to help protect items from damage during shipping is vital, as is leveraging the right-sized box so that you're paying only what is necessary for shipping costs.

But shipping frozen food brings additional challenges, and getting it right will likely be one of the most essential parts of your business.

Let’s outline some of the most common challenges when shipping cold food.

The government provides strict oversight on any business that deals with consumable products. The Food and Drug Administration (FDA) has a list of rules that anyone engaged in transporting these types of products must follow, including labeling requirements, regulations related to what kinds of materials can come in contact with food products, and rules for maintaining proper temperature during shipping.

These rules help protect consumers from potentially deadly foodborne illnesses and contaminated food products. Retailers who neglect these laws may be held liable for causing harm to the population and face fines, restrictions, or worse.

Frozen food must remain at an appropriate temperature to reduce the risk of spoilage and prevent bacteria from growing. This temperature control is achieved by using the proper packaging materials, like cold packs, insulated boxes, and dry ice, to help maintain freshness and temperature through every step of the shipping process.

Using strong, reinforced packaging may also be necessary to prevent crushing or puncture damage to boxes.

Certain foods and frozen products may require external temperature sensors. These sensors monitor the temperature throughout the shipping process – from start to finish – and can prevent products that hit unsafe temperatures from reaching your customers.

Food products have a limited shelf life, and your customers will want their purchases to arrive at peak freshness. If you're shipping cold or frozen food products, that window of time you must get the items from the warehouse to your customer's doorstep shrinks significantly. Ensuring fast delivery will mean planning ahead of time to ensure you have taken the necessary steps to expedite the shipping process.

There are many kinds of food products that businesses can ship to customers, and one that is rising in popularity is meat products. If your eCommerce store plans to sell meat products, you will need to learn how to ship frozen food.

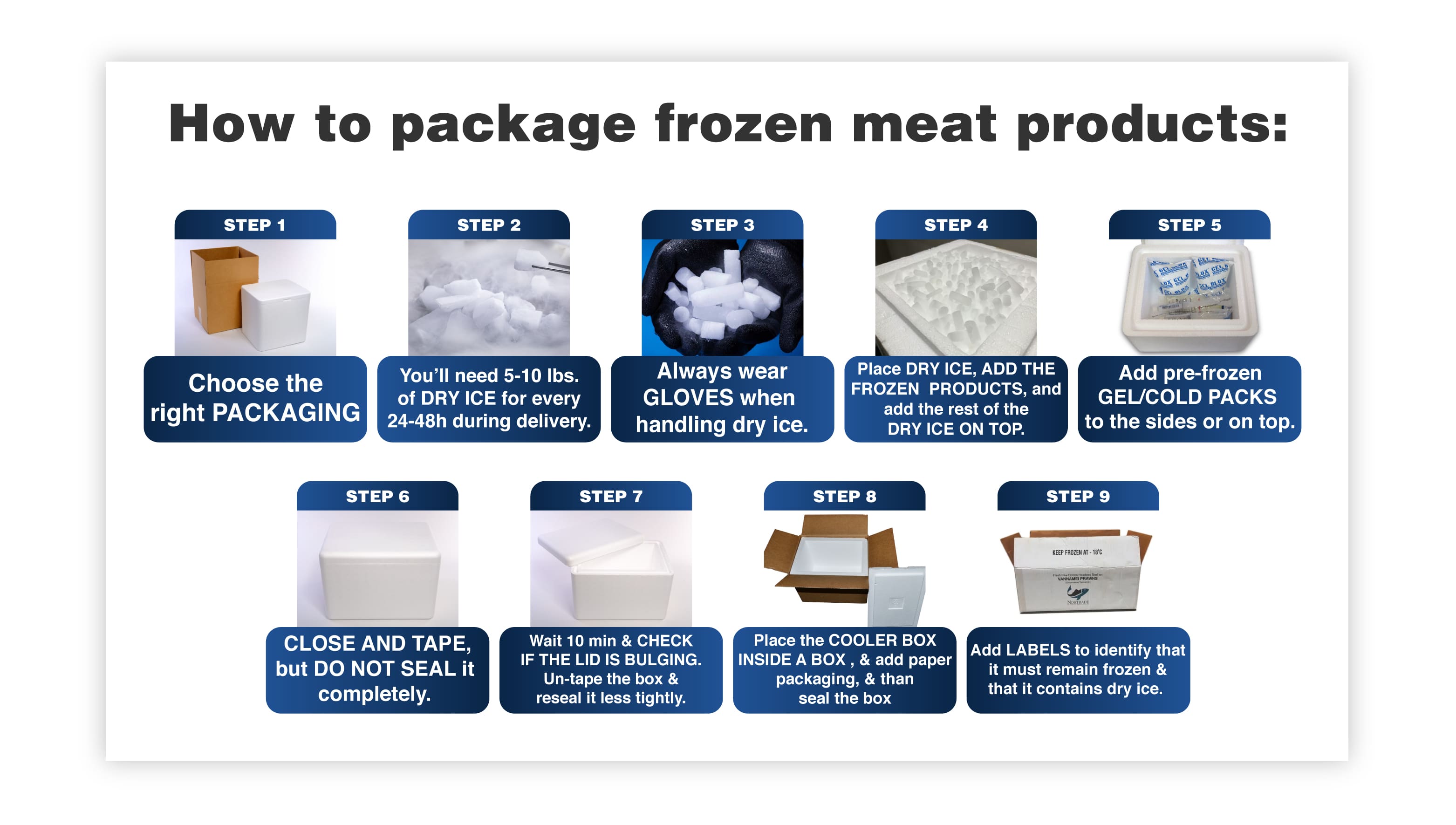

Cold food products must remain below 40 degrees Fahrenheit to prevent the growth of dangerous bacteria that can cause foodborne illness. Frozen food products should be shipped at 0% Fahrenheit to prevent items from thawing during the shipping process. Dry ice can keep products frozen during transport if the products reach their destination before the dry ice evaporates, or sublimates, back into a gas.

There are federal regulations related to the shipping of frozen meat products. In addition, different carrier companies may have rules and restrictions for what is acceptable and what is not. Make sure you understand these things ahead of time.

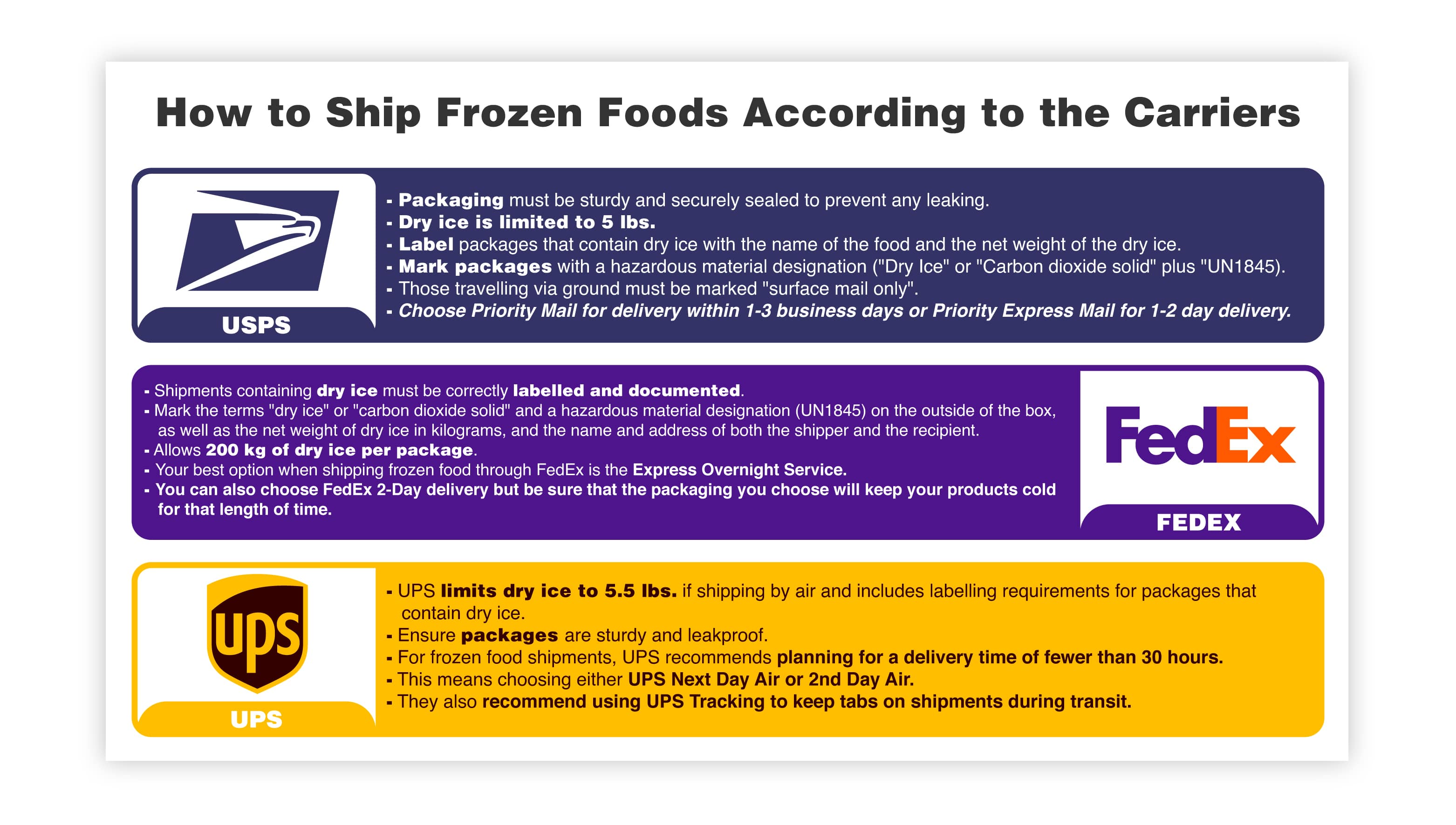

Most major carrier companies allow the shipment of frozen foods within the United States. However, each has different rules and regulations regarding these types of shipments. We’ve broken down the difference between the three leading carriers: USPS, UPS, and FedEx.

● USPS

The USPS remains one of the most cost-efficient ways to ship small to medium-sized products, including insulated packages. They do not offer specific cold or frozen food packaging for purchase or refrigeration services.

Packaging must be sturdy and securely sealed to prevent any leaking. Dry ice is limited to 5 lbs. per mail piece for air transport and must be in containers that permit the release of carbon dioxide gas.

Label packages that contain dry ice with the name of the food inside and the net weight of the dry ice. Mark packages with a hazardous material designation ("Dry Ice" or "Carbon dioxide solid" plus "UN1845).

Those traveling via ground must be marked "surface mail only." USPS requires a declaration for dangerous goods to be completed in triplicate and attached to the box's exterior.

Choose Priority Mail for delivery within 1-3 business days or Priority Express Mail for 1–2-day delivery.

● FedEx

The great thing about FedEx is the services for small businesses, including special considerations for retailers needing to ship frozen food. These services include dedicated containers and packaging options for temperature-sensitive medical and food products and temperature sensors to help monitor frozen shipments for thawing.

Shipments containing dry ice must be correctly labeled and documented. Mark the terms "dry ice" or "carbon dioxide solid" and use the hazardous material designation (UN1845) on the outside of the box.

Be sure to include the net weight of dry ice in kilograms, as well as the name and address of both the shipper and the recipient. FedEx allows 200 kilograms of dry ice per package.

Your best option when shipping frozen food through FedEx is the Express Overnight Service. You can also choose FedEx 2Day delivery, but be sure that the packaging will keep your products cold for that time.

● UPS

UPS is another suitable choice for shipping frozen food products because they have overnight and expedited delivery options. They also offer a Cold Chain services department to help businesses navigate cold product shipping, although it is mostly focused on freight deliveries.

UPS limits dry ice to 5.5 lbs. if shipping by air and includes labeling requirements for packages that contain dry ice. Ensure packages are sturdy and leakproof.

For frozen food shipments, UPS recommends planning for a delivery time of fewer than 30 hours. This delivery time means choosing either UPS Next Day Air or 2nd Day Air. They also recommend using UPS Tracking to keep tabs on shipments during transit.

Learning any new skill means the possibility of making some mistakes along the way, and the same is true of learning how to ship frozen food correctly. Because doing it right is so important for your business's success, ensure you understand the process completely before sending out your first shipment.

Here are some things to avoid and keep in mind to reduce your risk of making costly mistakes.

Like most other shipping errors, retailers make many mistakes around their choice of packaging. Poor packaging of frozen food items is certain to cause problems. Make sure you choose the best combination of packaging, including sturdy reinforced boxes, insulated cooler boxes, and high-quality tape.

Include dry ice or cooling gel packs, or both, to keep items at the right temperature during transit. Don’t forget the waterproof sheets or absorbent pads to soak up moisture. Ensure frozen shipments are delivered within 24-48 hours and schedule shipments at the beginning of the week to prevent delays over the weekend.

Dry ice is considered a hazardous material. If mishandled, it comes with a risk of burns and causes pressure to build up inside packages as it sublimates, which can lead to an explosion without proper venting.

Make sure you’re using the right amount of dry ice to keep your items frozen for the duration of their journey, but don’t use so much that the cost of shipping outweighs your profit.

Shipments that contain frozen or consumable items and shipments that include dry ice in the packaging, will require specific documentation and labeling. Do your research beforehand to ensure all required documentation and labels are present.

There are various options you can choose when creating a packaging system to ship frozen food. You should optimize each piece for the specific products you plan to ship and ensure that those items arrive at their destination intact and frozen solid.

We've listed some of the most common and effective choices below to help you build your frozen food packaging system.

Start with the insulation – Whether you choose a Styrofoam cooler box or a corrugated box with an insulated liner, make sure you use some form of insulation for your frozen products. Use a combination of methods for the best result. Once you have selected the type of insulated package you are using, add extras to keep it cold, such as:

Add the cooling method – Gel ice packs and dry ice are the surest way to keep frozen foods at the correct temperature. Although dry ice stays much colder, that protection is gone once the ice has completely sublimated. Gel ice packs don't stay nearly as cold but tend to provide cooling for a longer time.

Absorb moisture – Gel ice packs can create moisture as they melt, damaging the integrity of the packaging or potentially damaging the items inside. Adding absorbent pads or mats to the bottom of the box can help keep everything dry. You might also consider adding a plastic liner to prevent moisture from leaking.

Seal the box – If you’re using dry ice, ensure you don’t seal the box too tightly to allow the gas to escape. Choose a heavy-duty, high-quality tape that won’t come loose during transit.

Put the box inside a box – It's best to package frozen items in an insulated box or Styrofoam cooler. Then, place that package inside another larger corrugated box to help protect it from physical damage during shipping.

Don’t forget the labels – It’s important to properly label packages that include frozen items or dry ice. Don’t forget to include any required documentation.

Dry ice and cold packs are the two most effective ways to maintain the proper temperature when shipping frozen food. It will be up to you to decide which one to use or if it might be necessary to use both. Let’s learn a little more about each of these cooling methods to help you decide.

Cold packs, or ice packs, can maintain temperatures around 32 degrees Fahrenheit. This temperature is low enough to keep foods in a safe zone and stop the growth of bacteria. Cold packs are available in several forms, such as liquid or gel.

They are suitable for products that must be kept cold but do not need to remain frozen. They’re also useful for transporting items sensitive to extremely low temperatures.

Dry ice is the frozen form of carbon dioxide and can maintain a temperature of around –109.3 degrees Fahrenheit. This incredibly low-temperature threshold means frozen foods packed with dry ice will stay frozen, at least for as long as the dry ice is present. As dry ice evaporates or sublimates, it reverts to carbon dioxide gas. This transformation, as well as the extremely low temperature, is what classifies dry ice as a hazardous material.

Deciding how to keep your frozen food products cold during shipping will require weighing the pros and cons. The final answer should account for the cost and type of products you sell, how far you plan to ship them and how fast, and the quality of the packaging materials you use.

You should also consider one main difference between dry ice and cold packs – the complexity that using dry ice brings.

Overall, dry ice will always be the better choice for products that need to remain frozen. Cold packs do exactly what the name implies – they keep items cold, but they do not guarantee those items arrive fully frozen. This is especially true depending on the size and weight of the items.

Dry ice, although much colder, means an extra cost and consideration of regulations. Packages that need more than 5.5 lbs. of dry ice to maintain their temperature will not be eligible for air travel inside the U.S. and, therefore would need to travel via ground delivery.

Long-distance travel, like New York to California, would not be feasible for packages above that threshold because they would not make it to their destination on time. This means shipping several smaller packages, which could add to the shipping cost.

To make the right choice for you, consider the needs and capabilities of your business. Using dry ice and cold packs together in a single package will be the safest way to keep products cold – if you can afford the cost and manage the process.

When you ship frozen foods as a part of your business practice, there is a level of risk involved that is higher than if you were dealing in only non-perishable or non-consumable products. If a customer receives a damaged, non-consumable item from your store, they probably won't be happy.

But you, as the business owner, can remedy the situation by offering them a refund or shipping a replacement item for free.

However, if a customer receives a shipment of frozen food that was not kept at the appropriate temperature during transit, there is a greater risk to that customer. If they consume items that are contaminated or rife with bacteria, there is a chance they could get very sick.

That opens you up to liability and means the potential loss of that customer forever. Here are some major risks and concerns that eCommerce stores that ship frozen products will face.

Fluctuating temperatures – The journey from a warehouse to a customer's house includes several environmental changes. From the warehouse itself to the back of a delivery truck, the cargo holds of an airplane, to the destination climate itself - each package faces the risk of ending up somewhere where temperatures are suddenly extremely cold or extremely hot.

Fluctuating temperatures put your shipments at risk of either melting faster than expected or experiencing damage from frost. This means a potential for lost or damaged products because of circumstances that you cannot control.

Humidity – Humidity is the enemy of any shipping process because it builds up easily inside shipping containers and delivery vehicles. Excess humidity is essentially water in the atmosphere, and when that water meets a shipment of frozen food, it can wreak havoc. Humidity can melt frozen items faster or even settle on frozen items and refreeze them. It can also cause damage to packaging materials.

Delays – Frozen food shipments are not only temperature-sensitive but time-sensitive as well. Any unplanned delays during transit put your frozen items at risk of thawing, making them unconsumable.

Travel delays can result from inclement weather along the delivery route, broken-down equipment, and other unexpected situations. That's why optimizing delivery routes is important (choosing the shortest time frame, and taking precautions with your packaging).

The cost of shipping frozen food will depend greatly on the size and weight of the package in question and the components you choose to use to keep the items cold. It will also depend on which carrier service you choose and what type of delivery service you decide on. Faster and bigger are always more costly than slower and smaller.

Here are the cost components of shipping frozen food:

In general, most frozen food deliveries will cost between $30 and $150. For smaller, lightweight items we recommend using a mix of carriers to ensure you capture the best rate for every shipping zone your customers are located in. With BUKU Ship's technology you can customize which carriers and rates you want displayed at checkout ensuring you provide your customers with the services that most fit your needs.

If you are planning on operating an eCommerce business that ships frozen food, it's vital that you learn the process ahead of time. Learning as you go might work in some instances, but here it can potentially cost your money, customers, and your reputation. As a business owner, these are things you must protect.

Be aware of the risks that cold food shipping brings and take steps to protect your products from those risks, such as:

Once you unravel the mystery of shipping in general and understand the different methods of keeping frozen items at the proper temperature, finding the most cost-effective packaging, cooling materials, and carrier company become a task. Make sure you consider all the details involved with the cost of shipping frozen food when setting your prices for sale and delivery so you don’t lose money in the end.

Shipping cold food products take careful planning and oversight. It's a balancing act between risk and reward, cost, and revenue. But if done correctly and with enough foresight, it can be very profitable.

The supply chain is a term used to describe all the components required to transport goods from beginning to end, from production to the end...

A smart warehouse is a large building where raw materials and other consumer goods are stored using machines, computers, comprehensive software, and...

Direct-to-consumer (DTC) fulfillment is a strategy that helps brands sell and deliver their products directly to customers more efficiently while...