Cold Chain Logistics: Management Challenges & Solutions

The supply chain is a term used to describe all the components required to transport goods from beginning to end, from production to the end...

11 min read

BUKU Marketing

:

Jun 21, 2023 1:00:00 PM

BUKU Marketing

:

Jun 21, 2023 1:00:00 PM

In today's e-commerce industry, the supply chain is more critical than ever before. The post-Covid recovery taught many businesses a valuable and costly lesson about how fragile the supply chain is and how the collapse of one or two links in that chain can bring down the entire thing.

Table of Contents

1. Critical Challenges In Supply Chain Visibility

2. The Benefits Of Supply Chain Visibility

3. How To Improve Supply Chain Visibility

4. Real-Time Tracking & Tracing

5. Supply Chain Analytics & Predictive Insights

6. Supply Chain Risk Management

7. Supply Chain Visibility Future Trends & Outlook

A survey conducted in 2021 of senior supply-chain executives found that 30% had implemented new technology to gain greater visibility. Despite those investments, the visibility into their supply chains remained limited.

About half of the respondents reported understanding the location and risks to their tier-one suppliers. Still, only two percent said they had any visibility into the third tier and beyond.

Supply chain visibility is tracking the movement of goods and products in transit from raw materials to the final customer. Accurate visibility can improve customer service, reduce costs, and help mitigate the risks inherent in the chain itself.

Many e-commerce retailers have turned to third-party logistics providers to enhance their visibility and control of their supply chain.

3PLs help companies save money and improve efficiency by providing the tools they need to gain visibility and focus on their core competencies. Implementing technology and software in the right places is another way to gain control.

This article will explain what it means to have supply chain visibility, why it matters, and how to achieve it for your e-commerce or retail business.

Supply chains are complex systems that move goods and products from one point to the next until the final link leads the products directly to the customer. With so many moving parts and partnerships working in tandem, there are bound to be challenges. For e-commerce and retail businesses, many challenges come from a need for more visibility.

Think of it like this: if you can’t identify a problem, you can’t fix it. Supply chain visibility allows businesses to pinpoint weaknesses in their logistics systems.

Here are some of the most common challenges companies face regarding their supply chain visibility:

In the years following the outbreak of Covid-19, the cost of shipping exploded worldwide. For example, the cost of shipping a container across the ocean increased seven-fold in the 18 months following March 2020. The skyrocketing costs caught many businesses off guard, especially when those costs trickled down to the business owners themselves.

This is just one example of why cost control is vital for businesses. The supply chain is connected, and whatever affects one partner inevitably affects them all. To combat these challenges, companies need to negotiate better prices with suppliers and work to optimize supply chain networks.

Many businesses are turning to technology to help them gain visibility into their supply chain to weed out waste and make smarter cost-control decisions.

The economy has been on rocky ground since the pandemic. Even now, when things are regaining some normality, the health crisis uncovered how vulnerable the global supply chain is to influence outside.

And it’s not just the pandemic that is concerning; global politics, trade agendas, consumer demand, war, and even weather events can stall a supply chain.

Planning and risk management are critical for businesses, and supply chain visibility is the best way to achieve these goals. When you can see everything clearly, you can plan for the worst. Companies must keep ahead of potential catastrophes and constantly reassess the solvency of their supply networks.

Even in e-commerce, people are at the heart of a business's success. Partners are implementing new and advanced technologies to help streamline operations. For these initiatives to be successful, there must be skilled workers. Depending on their scale, businesses need to put knowledgeable people in charge of their supply chain and logistics systems.

When the right people are in the right place, businesses can thrive. But a lack of skilled talent sometimes means companies take shortcuts in the talent pool and simply hire to fill spots rather than look for skilled workers.

According to one survey, only 27% of leaders believe they have the talent to meet supply chain performance requirements.

Supply chain visibility can be challenging to achieve. Many businesses need help seeing into the details of their supply chain and instead are forced to put their faith in their supply chain partners to do things the right way.

Consider this: would a successful business trust any other part of its operations to someone else without maintaining some oversight of that operation? Probably not. Doing so puts companies at risk because when a partner fails to uphold their responsibility, the consequences fall back onto the business owner. An unhappy customer won’t accept excuses about a lousy supply partner from a business. They’ll simply take their money elsewhere.

Visibility into every aspect of the supply chain allows businesses to spot and remedy problems, cut costs, optimize operations, and produce better customer results. Technology is one of the best ways companies can achieve this visibility.

Building a sustainable and environmentally responsible operation is vital for businesses today and even more critical to their customers. Consumers are looking to buy from companies who are demonstrating a commitment to these goals and will respond poorly when a business fails to do its part.

According to the EPA, supply chain emissions are 11.4 times higher than operational emissions, meaning approximately 92% of an organization’s total emissions come directly from the supply chain.

Implementing ecologically responsible transportation methods and partners is vital for businesses to maintain a reputation of honesty and transparency.

Supply chain visibility is tracking materials, goods, and products as they move through the logistics network. Seeing into the supply chain provides numerous benefits for businesses, starting with the ability to control costs and ending with protecting their reputation with customers.

Check out this list of benefits offered by supply chain visibility.

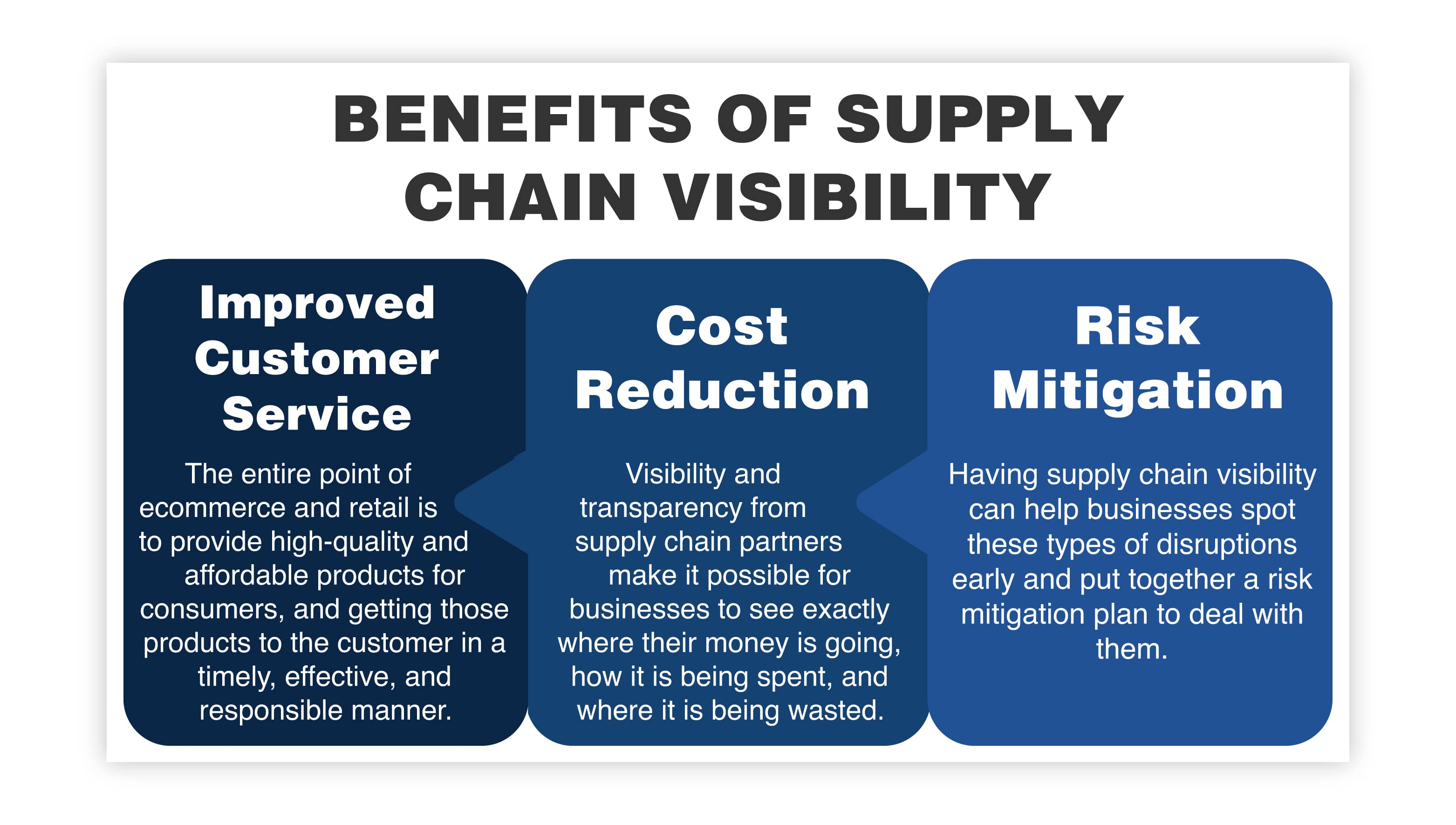

The customer is the last stop in the supply chain and the most essential partner. The entire point of e-commerce and retail is to provide high-quality and affordable products for consumers. And that means getting those products to the customer promptly, effectively, and responsibly.

One portion of supply chain visibility is tracking deliveries of goods directly to the customer and providing real-time data to the customer about their packages.

Consumers today want fast delivery, sometimes even overnight, and they want to be able to see their packages in transit every step of the way. To provide this, businesses must have access to real-time data and tracking capabilities.

Identifying and eliminating waste in the supply chain can save organizations a great deal of time and money. Visibility and transparency from supply chain partners make it possible for businesses to see exactly where their money is going, how it is being spent, and where it is being wasted.

Low-quality materials, goods, and products damaged in transit, poor inventory storage practices, and more can cost businesses millions of dollars. Having visibility into the supply chain helps companies to spot these problems and deal with them upfront.

As mentioned before, the supply chain is vulnerable to all kinds of risks at both the macro and micro levels. While outside political and economic events can affect a logistics network, even minor disruptions to one partner in the network can ripple through to a business.

Having visibility into the supply chain can help enterprises to spot these types of disturbances early and enable them to create a risk mitigation plan to deal with the blowback.

Building a strong and reliable supply chain is vital for a retail or e-commerce business. Doing it efficiently means gaining visibility into the details of that network. Supply chain partners help fill in the blanks and move goods from one place to another.

Businesses should seek supply chain partners who want to increase visibility and transparency and offer the tools and services to provide those things. E-commerce businesses must do their part to increase supply chain visibility by employing the right strategies and demanding better visibility from partners.

Here are some ways to improve supply chain visibility.

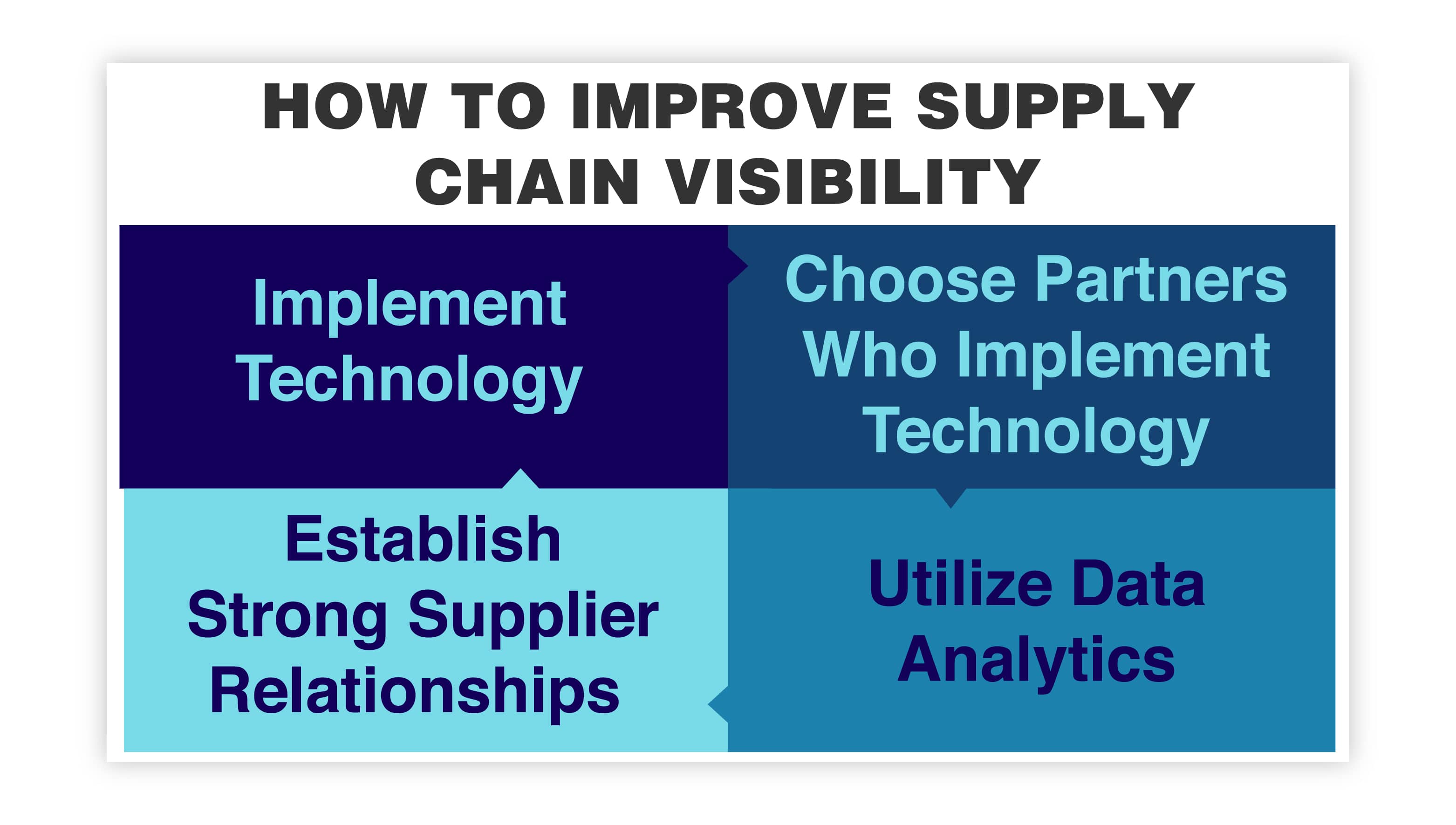

Supply chain and logistics management software is one of the most effective ways for businesses to increase visibility. These types of software allow transparency and communication between companies and their supply chain partners. Look for systems that can integrate with other platforms and provide the most oversight into the logistics network.

Many businesses are turning to 3PLs to expedite and optimize their supply chain. Outsourcing part of the logistics operation to a 3PL can provide numerous benefits, but businesses must be picky about their choice of partner. Look for 3PL providers taking advantage of technologies and automation to streamline their services and provide transparency – and the benefits will trickle down to the business.

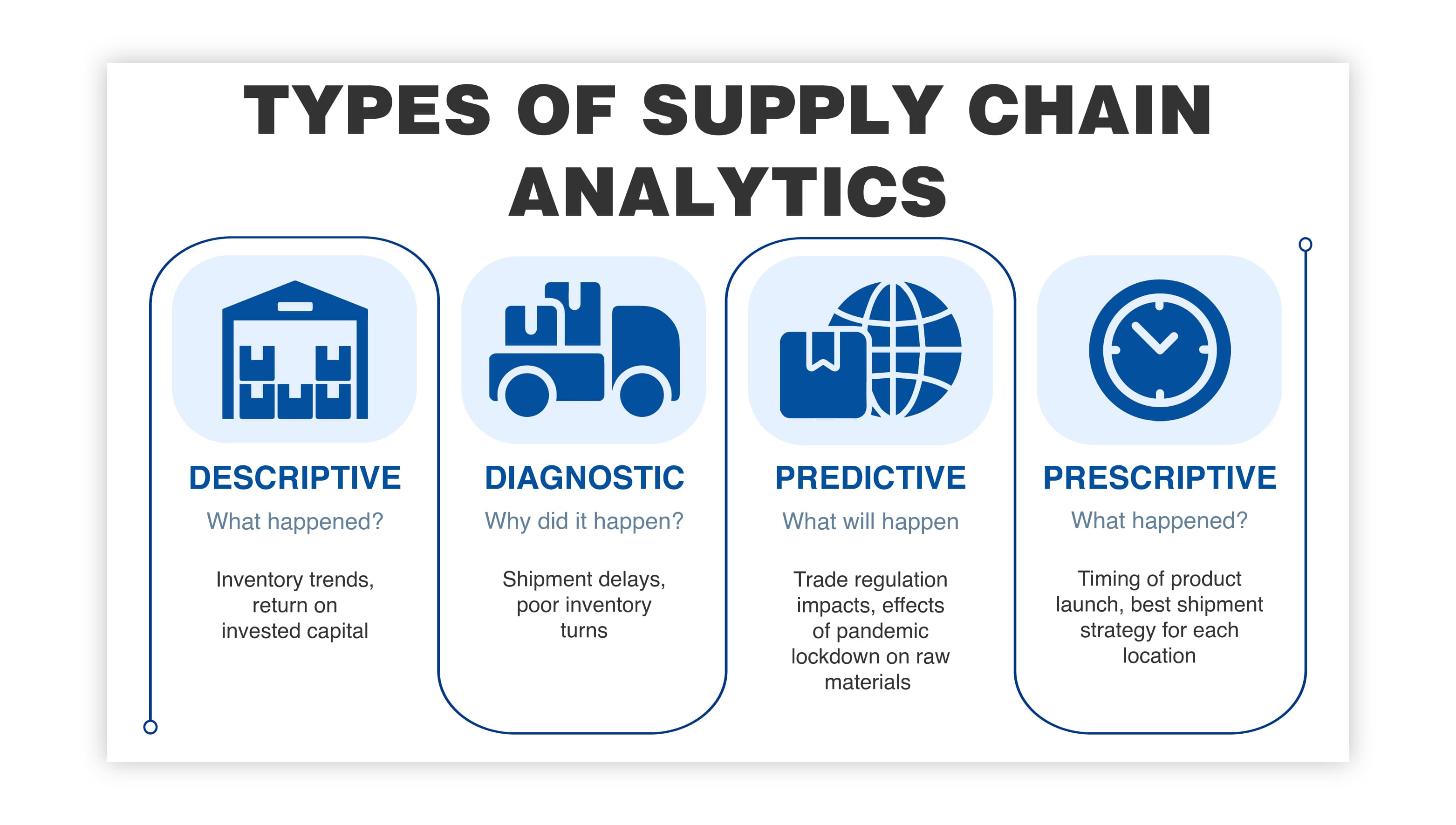

Businesses today have access to more data than ever before, both historical and real-time. E-commerce and retail companies need to take advantage of that data by analyzing it effectively and using it. Supply chain partners should be willing to work with businesses to provide access to accurate data.

Building solid relationships with suppliers is vital and gives businesses the leverage to negotiate better prices. Loyalty between suppliers and companies can mean a willingness to work together through difficult times and disruptions. A solid relationship with suppliers can also provide greater insight and visibility into operations.

The supply chain represents an actual link between suppliers and customers. Businesses use this chain to move products and goods from one point to the next until the final product reaches its destination at the customer's doorstep.

Today's consumers are more demanding than ever before. They understand the capabilities of technology in terms of real-time tracking and shipping information. And they want to buy from businesses that are providing those services.

Tracking and tracing involve two processes that work together to ensure goods and materials get where they’re supposed to be on time and in good condition.

Tracking involves providing information regarding the movement of goods from one location to another and the stops made along the way. Tracing consists in tracking not only the direction of the goods but also the condition of those goods, including their temperature and storage conditions.

Real-time tracking and tracing are vital when it comes to that final leg of the supply chain journey because of the expectations of that consumer waiting for a delivery. But for businesses, tracking and tracing must occur throughout the supply chain, from start to finish.

Forbes recently reported that a lack of visibility across the extended supply chain is one of the biggest challenges companies face today. Businesses across the supply chain network, from e-commerce retailers to warehouses and manufacturers, are implementing technology to solve this problem.

Access to real-time tracking and tracing information helps improve supply chain visibility and allows businesses to pinpoint where failures are happening. This helps cut costs, reduce waste, and improve operational efficiency.

Click here to learn more about BUKU's newest tracking feature! Increasing the transparency and effectiveness of any eCommerce brand.

Supply chains have become more complex, and logistics partners are using technology to solve those problems. This has created a new need within many logistics networks, and that’s the need to maintain complex technological systems.

3PLs and warehouses use automation and robotics to carry out tasks, from picking and packing to moving inventory around.

Integrated software systems tie together all the steps in the supply chain into one moveable and manageable structure, which is excellent for businesses looking to improve supply chain visibility.

But when something goes wrong at any level of these systems, it can hamper a business.

Maintenance is a requirement whenever technology and machinery enter the equation. Businesses today understand that a proactive approach to maintenance tasks is much more cost-effective and efficient than reactive maintenance.

Instead of waiting for a piece of machinery to break down, organizations are using real-time condition tracking and data to predict when maintenance will be necessary – virtually expecting when a piece of machinery will break down.

Businesses should seek supply chain partners who provide the best tools and systems to do the job This is an excellent example of that. Having partners who utilize predictive maintenance and implement it within a business's systems can help cut costs while increasing efficiency. And like everything, these goals have a direct effect on customer satisfaction.

In general, building a supply chain that features proactive partners rather than reactive ones provides a better sense of security and more excellent resiliency.

Supply chain visibility provides many benefits for businesses. One of the biggest and most important is the ability to respond and react quickly.

Business is a balancing act; nowhere is that more apparent than within the logistics network and supply chain. When one block is out of balance, the entire thing can topple, stopping a business in its tracks.

It only takes looking back over the past several years to see how vulnerable the global supply chain is. For example, Covid forced the shutdown of manufacturing companies around the world.

Suddenly businesses needed the ability to get the products they needed. Shipping costs skyrocketed, and delays went from a few days to a few months overnight.

These disruptions were large-scale global events that made the supply chain tumble and businesses pay the price.

If there is anything positive that has come from the years after the pandemic, it’s the lessons learned. First and foremost, businesses need to have a contingency plan. Not every potential disruption will be a large-scale global event, but even minor disruptions within the supply chain can have a crippling effect on businesses. Having increased visibility and transparency in the supply chain helps companies:

Supply chain visibility helps businesses understand how the moving parts of the global supply chain connect and work together. Regularly reviewing logistics systems and potential risks within those systems can help companies to build contingency plans that will keep them afloat when the next big or minor collapse occurs.

The last few years have been a roller coaster ride for businesses of all kinds, especially those who rely on the global supply chain for success. As we’re moving through 2023 and beyond, businesses are looking for ways to weather the inevitable hills and valleys headed their way.

And that means pushing progress and implementing new and advanced technologies to help them do it better the next time around.

What’s the future look like for e-commerce and retail? Here are a few predictions:

Public expectations surrounding sustainability and eco-friendly practices are more extensive than ever before. As people become more aware of the environmental impact of their everyday activities, and even their buying habits, they are looking at big business and industry to lead the way.

That means businesses need to make smarter choices at every level. This demonstrates a commitment to building a sustainable business and builds consumer confidence and trust.

Aside from that, focusing on waste reduction and sustainable development helps businesses cut costs in the long run. Waste is just what it sounds like – wasted resources, materials, and money. The need for sustainability and waste reduction is here to stay.

Consumers today demand fast, efficient, and affordable delivery. And when we say fast, we mean quickly. Recent surveys show that more than 40% of U.S. consumers expect online delivery to reach their doorstep in two to three days. 27% expect same day or next day delivery. And a growing number expect affordable, or even free, delivery within that time frame.

Part of this is the result of the “Amazon Effect.” Big players like Amazon and other online retailers have conditioned consumers to expect super-fast delivery, and to remain competitive, and businesses need to find ways to keep up.

Optimizing the supply chain and putting the right partners in place is the first step to providing fast customer delivery. Focusing on last-mile delivery will likely be a driving factor for business from here on out.

The rising popularity of third-party logistics providers has proven that e-commerce and retail businesses are looking for solutions. 3PLs are answering that call by diversifying the services they offer to those businesses. 3PLs are implementing automation and robotics to keep up with a rapidly changing landscape and remain competitive with big players like Amazon.

Businesses need better protection from potential risks and disruptions in the supply chain, and 3PLs are working to provide that by becoming more flexible, adaptable, and transparent. This relationship between businesses and 3PLs will likely become more important than ever as we move into the next decade.

For additional information regarding 3PLs contact BUKU!

Much like every other industry on the planet, technology is the wave of the future. Advancements in the development and availability of these technologies are changing how businesses run for the better. Progress in these areas is inevitable and likely to continue.

To remain competitive, businesses must implement technology that increases supply chain visibility. This will help them build a more resilient supply chain, cut costs, and improve customer satisfaction. And it will help them make a firewall against future disruptions to have confidence in their ability to weather whatever the future holds.

To sum up, supply chain visibility is essential for businesses of all sizes. The ability to see into every step of the supply chain, communicate with partners, and build relationships gives companies a better chance of success. It helps them identify problems quickly and make better decisions.

Companies should strive to build a better supply chain and gain a better perspective on logistics operations. They can accomplish this by incorporating technology into their operations and seeking partners who do the same.

Investing in technology that provides real-time data and analytics can give them the information they need to solve problems and streamline their operations. And building better relationships with suppliers will help them weather future disruptions and uncertainties.

Businesses that embrace supply chain visibility will be better able to mitigate risk. They will be better able to satisfy customers with fast, accurate delivery. And they will be better positioned to succeed in the future.

The supply chain is a term used to describe all the components required to transport goods from beginning to end, from production to the end...

A smart warehouse is a large building where raw materials and other consumer goods are stored using machines, computers, comprehensive software, and...

Direct-to-consumer (DTC) fulfillment is a strategy that helps brands sell and deliver their products directly to customers more efficiently while...