Cold Chain Logistics: Management Challenges & Solutions

The supply chain is a term used to describe all the components required to transport goods from beginning to end, from production to the end...

12 min read

BUKU Marketing

:

Jun 28, 2023 1:00:00 PM

BUKU Marketing

:

Jun 28, 2023 1:00:00 PM

A warehouse is typically considered a building where goods and products are stored until it’s time to ship them to the customer. And while this definition still holds, today’s warehouses are much more than that.

That’s because businesses have discovered that proper warehouse management can do wonders for their bottom line, and they’re actively taking steps to take advantage of that fact.

Table of Contents

1. How Does Proper Warehouse Logistics Benefit eCommerce?

3. The Three Main Types Of Warehouse Layouts

4. Tips for Maximizing Warehouse Space & Optimizing Design

6. Choose the Right IMS for Your Business

8. Best Practices for Order Fulfillment

9. Warehouse Automation & Technology

10. Types of Warehouse Automation Tools

12. Cost Efficiency & Time Savings

13. Buku – Helping Ecommerce Businesses Optimize Shipping

14. Customer Satisfaction & Retention

15. Future Trends & Innovations

The eCommerce industry is booming and is only expected to keep growing as consumers go online for a more significant percentage of their shopping. According to experts, global eCommerce sales are forecast to reach $6.07 trillion by 2024.

Ecommerce companies are no longer one-person operations using a spare garage for inventory storage but multi-million-dollar operations. More sales mean a greater need for storage space and a greater understanding that every aspect of a company's activities affects its customers, competitiveness, and success.

Warehouse logistics is the process of planning, operating, and managing goods within a warehouse to meet business objectives. When done correctly, warehouse logistics can minimize operating costs, improve customer satisfaction, and help companies build a competitive advantage.

This article gives an in-depth analysis of warehouse logistics and how it has become so crucial in the way warehouses operate. Plus, we’ll look at some of the biggest emerging trends in the industry and how technology is changing how warehouses operate.

Warehouse logistics is a growing field of interest for eCommerce businesses. Gone are the days when goods and products were stored away in readiness for sale. Now, companies are looking for greater control and oversight of every aspect of their warehousing process – for good reason.

Warehouse management processes have a trickle-down effect on virtually every aspect of an eCommerce company.

Here are a few ways warehouse logistics can benefit businesses.

Research shows that shrinkage, or the loss of inventory for reasons other than sales, costs businesses around $62 billion annually. Having systems that improve inventory accuracy and storage practices can save companies money by keeping closer track of inventory levels.

Improved accuracy and efficiency also come from more optimized ordering, picking, packing, and shipping processes. For the customer, this aspect of warehouse management is what matters most. Mistakes in this area can cost more than dollars – they can cost customers who are unlikely to forgive mistakes.

The ability to see an operation's details gives business owners the information they need to make better decisions. And it gives them the ability to pinpoint areas that need improvement. For example, high-return items cost companies money and customers. Visibility allows companies to see scenarios like this and rectify them easily.

Cost is an important part of the retail equation. Lowering operational costs means selling products at a lower price and still making a profit – and that’s the essence of business. By streamlining and optimizing operations, warehouse logistics can help eCommerce businesses save money on order processing.

At the core of the retail business is the customer. Getting the right product to the customer as quickly and efficiently as possible is critical for eCommerce businesses trying to maintain a competitive edge in today’s market. Customers have no problem jumping ship to another retailer if they’re not satisfied with their delivery's accuracy, speed, or visibility.

Warehouse logistics encompasses every aspect of warehouse management, including the movement of goods through the warehouse from the moment they arrive to the moment they are shipped to the customer. Expediting that movement can help save businesses time and money, and that's why warehouse layout and design come into play.

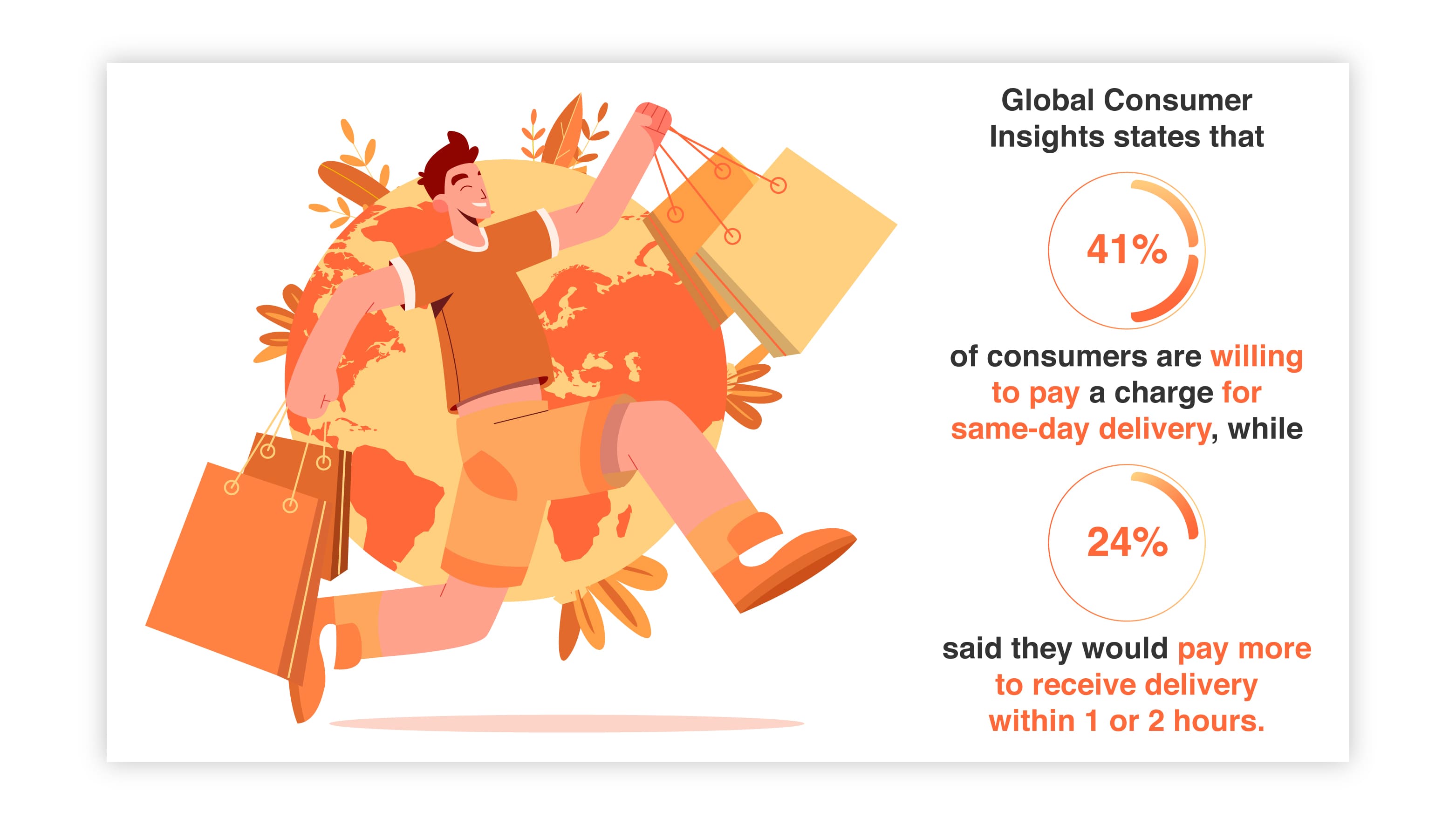

The time it takes to move goods around the warehouse or locate products when needed adds to the time necessary to get products to the customer. Global Consumer Insights states that 41% of consumers are willing to pay a charge for same-day delivery, while 24% said they would pay more to receive delivery within one or two hours.

What does that mean for eCommerce businesses? Offering fast, accurate delivery is vital for eCommerce businesses today, but pulling it off successfully means ensuring every aspect of warehousing is optimized.

A warehouse includes several areas used to stage or store goods and products. Typically, there are five distinct areas within a warehouse, including:

Dynamic Storage – For high-demand items that need to be located closer to the packing and shipping areas.

Static Storage – Typically holds items that don’t need to be moved around often or quickly using a racking system.

Staging Area – Used to manage incoming or outgoing products, including packing and unboxing.

Shipping Area – Used to prepare, hold, and load outgoing packages.

Receiving Area – Used to receive, unload, and record incoming deliveries.

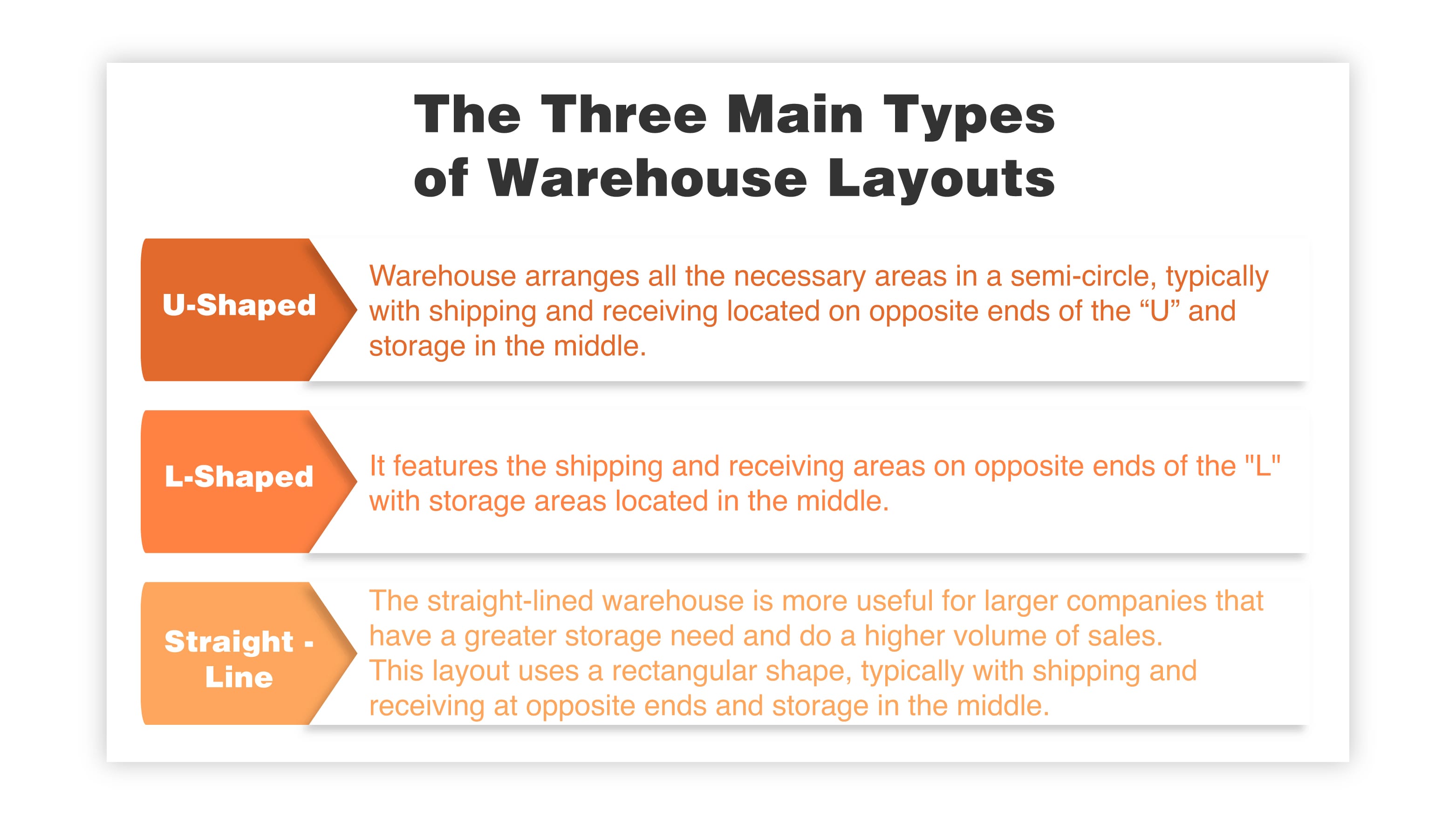

Probably the most common warehouse layout is the U-shape. A U-shaped warehouse arranges all the necessary areas in a semi-circle, typically with shipping and receiving located on opposite ends of the “U” and storage in the middle. This helps separate the flow of goods and expedite the movement between storage, shipping, and receiving.

The L-shaped warehouse is less common and typically chosen because of the shape of the warehouse building. It features the shipping and receiving areas on opposite ends of the "L" with storage areas located in the middle.

The straight-lined warehouse is more beneficial for larger companies that have a greater storage need and do a higher volume of sales. This layout uses a rectangular shape, typically with shipping and receiving at opposite ends and storage in the middle.

This creates a straight flow from the receiving end to the storage area and through to receiving. Buildings must have separate loading and unloading spaces on both ends to accommodate the straight-line design.

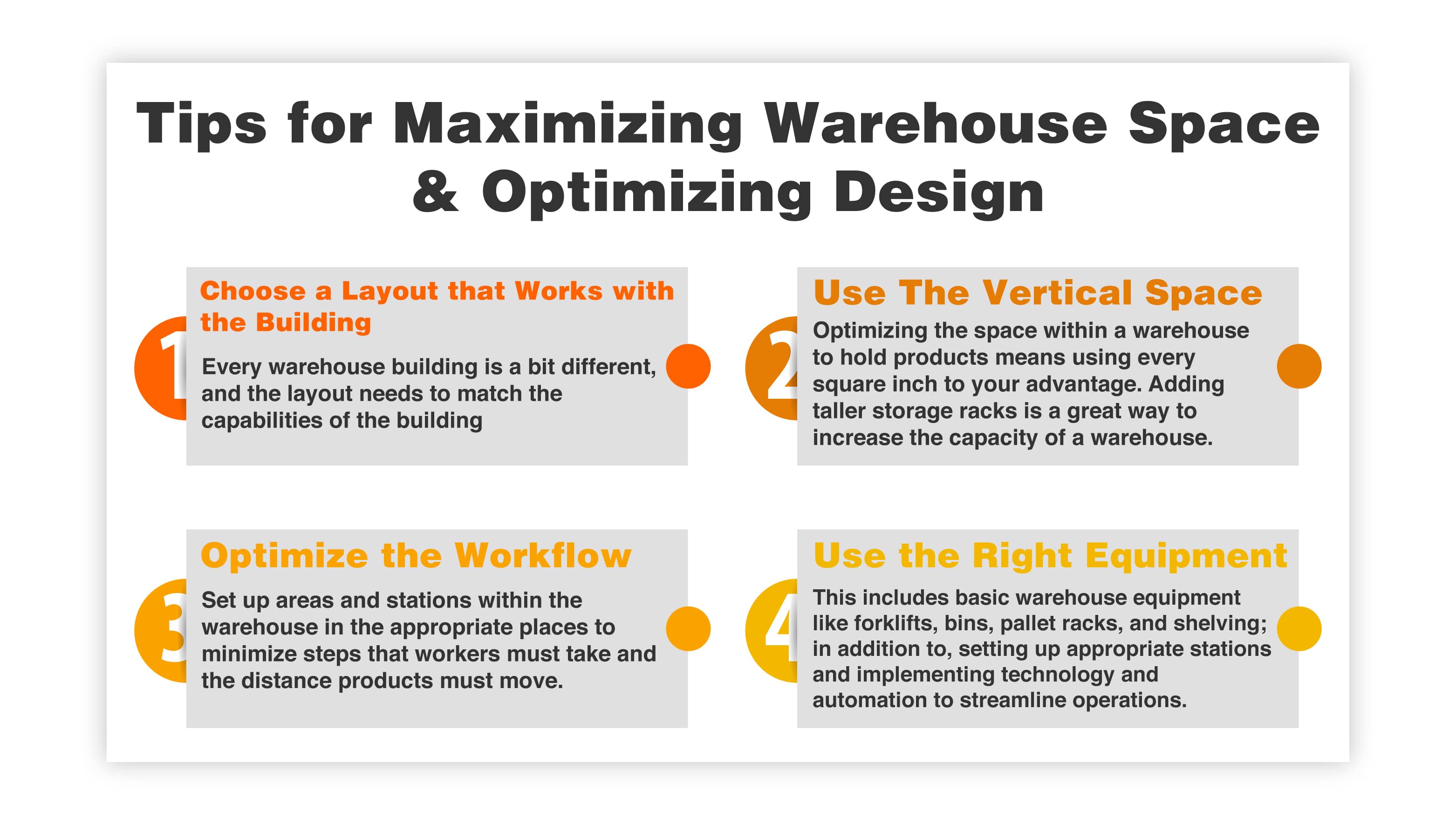

Every warehouse building is a bit different, and the layout needs to match the capabilities of the building. For instance, where the loading and unloading docks are located will affect which structure best suits the building.

Optimizing the space within a warehouse to hold products means using every square inch to your advantage. That means using the vertical space as well as the horizontal. Adding taller storage racks is a great way to increase the capacity of a warehouse. Be sure to store lighter-weight products higher and heavier products down low for safety.

The flow of goods and products through a warehouse should be seamless. Set up areas and stations within the warehouse in the appropriate places to minimize steps that workers must take and the distance products must move. Avoid bottlenecks and back-and-forth movement whenever possible.

Using the right equipment is crucial for a warehouse to operate efficiently. This includes essential warehouse equipment like forklifts, bins, pallet racks, and shelving. But it also includes setting up appropriate stations and implementing technology and automation to streamline operations.

One important component of warehouse logistics is the inventory itself. Proper inventory management is crucial; nothing else will matter without getting that part right.

Think of it like this: you’re a customer placing an online order. All is good with the world until you get a message letting you know that the item you ordered isn’t in stock. Considering that 56% of retail business leaders say their inventory information is inaccurate, it’s a distinct possibility. Are you going to forgive that error? Or is it more likely that you will take your business elsewhere?

Having accurate inventory data requires proper inventory management. And that will only be beneficial for eCommerce companies. Here are some of those benefits:

Inventory management includes keeping an accurate count of the inventory on hand and where that inventory is located within the warehouse. Expediting the time it takes to find a product when a customer places an order cuts the processing time, which saves businesses money and creates a happier customer.

Retail demand is a fickle beast, and meeting demand means keeping the right amount of inventory on hand. But keeping too much inventory takes up unnecessary space and eats up operational dollars.

It can also lead to shrinkage, especially if the inventory is perishable. Inventory management helps businesses balance inventory on hand with demand, so there is never too much or too little.

The importance of balancing demand with inventory levels becomes even more apparent when a high-selling item goes out of stock. Suddenly, a big seller is unavailable, and not only are all those potential sales lost, but also the customers. Accurate inventory management and forecasting can avoid costly stockouts.

Customers are happiest when they receive the products they want when they want them, and in the shortest possible time. In doing business, customers are unforgiving, and one mistake can cost a company what would otherwise be a lifetime customer.

An Inventory Management System can help eCommerce companies properly track and manage their inventory from start to finish. These systems are becoming more crucial, especially for businesses with a large sales volume. Gone are the days of paper and pencils. Instead, complex, intuitive systems have taken over.

With so many different options, choosing the right inventory management system can be tricky. Here are some questions to answer before selecting an IMS.

What is the size of the business?

What types of products do we sell?

What are the needs of the business?

What features does the system offer?

What size is the budget?

Answering these questions thoughtfully will help businesses select the IMS that is best suited to their needs and requirements without spending exorbitant amounts of money on a system that is too complex or making the mistake of going too simple to meet the needs of the business.

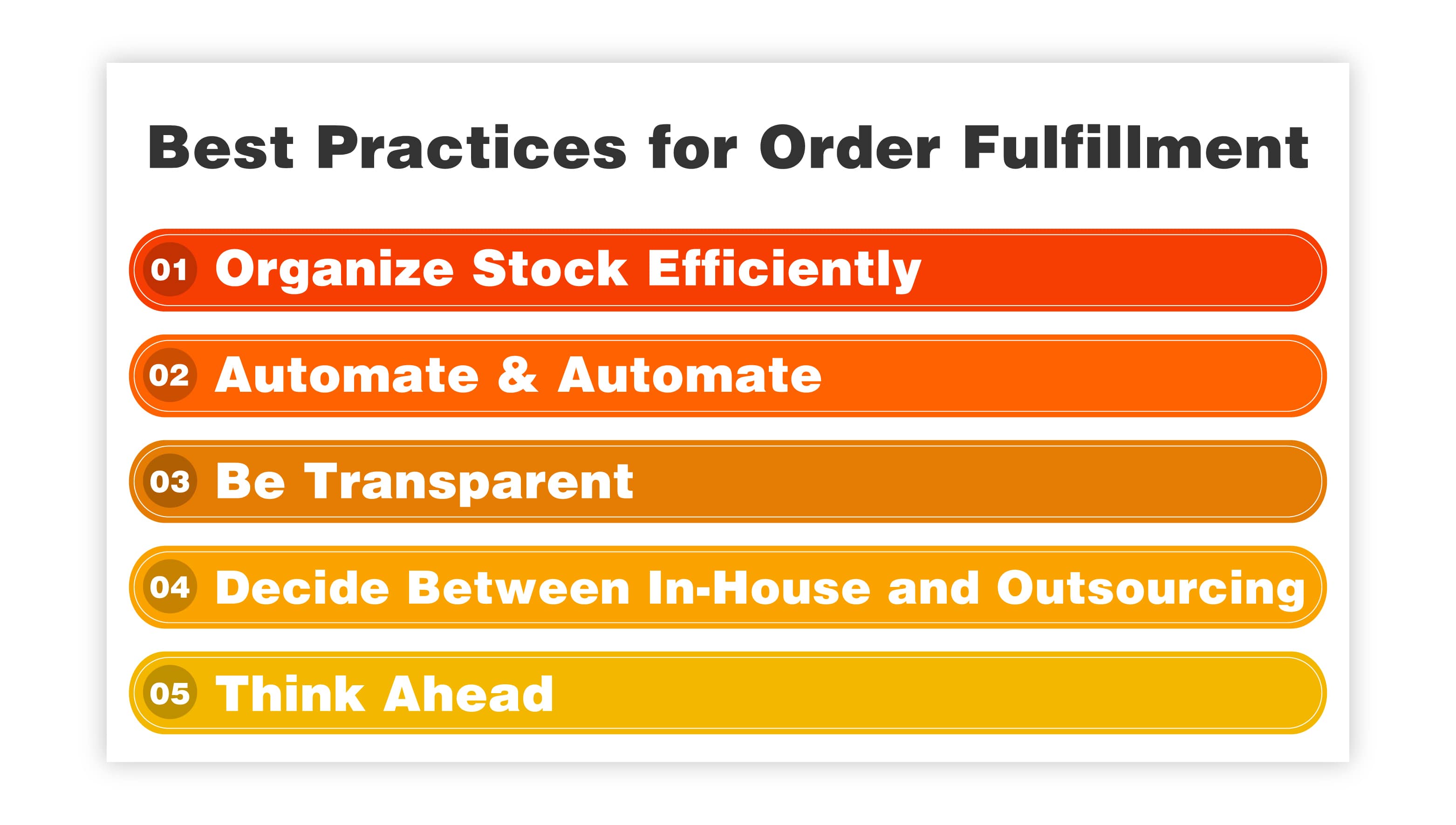

Order fulfillment is receiving, picking, packing, and shipping orders. These are the primary activities within a warehouse, and proper warehouse logistics must consider how to streamline these operations. Doing so will directly affect a business’s ability to satisfy a customer.

Let’s break down the steps of order fulfillment:

A big part of optimizing the order fulfillment process is giving warehouse workers the tools to locate and move products when they are needed quickly. Warehouse layout and design have an effect, but so does proper inventory management, organization, and planning.

Order fulfillment was a purely manual process, requiring warehouse workers for every step. But today, many of the activities necessary for order fulfillment are automated. Implementing the right technology to help optimize and streamline the order fulfillment process can save companies time and money.

Online consumers are more educated and demanding than ever. With huge corporations like Amazon running the market, consumers have come to expect not only fast accurate delivery but complete transparency throughout the process.

The ability of a company to process orders quickly will determine how fast a delivery reaches a customer. And since 67% of customers would be less likely to shop from a company that does not inform them when a package is delayed, transparency into the process is vital.

Many eCommerce businesses today choose to take advantage of third-party logistics providers. A 3PL can offer order fulfillment services alongside inventory management and warehousing services.

If the size and scope of your business are large enough to benefit from outsourcing the logistics process, then a 3PL could be the most cost-effective choice.

Every strategy in business should consider where the company will be in two years, five years, or ten years. When choosing an order fulfillment strategy, make sure the future size and scope of the businesses are included in the considerations. That way, when it comes time to scale, the proper framework will already be there.

Warehouse logistics has become more critical, and more complex, over the past several years. That’s because more companies are turning to advanced technology to help them do a better job with warehouse management. We have entered the age of automation, and its effect on the logistics and eCommerce industries has been immense.

Warehouse automation is the process of implementing technology that automates the activities within a warehouse, eliminating the need for human labor. Automation has incredible benefits for retail businesses, including:

Warehouse automation is an immerging industry, and the tools available are becoming more valuable and diverse daily. Here are some of the typical tools you will find in an automated warehouse.

Goods-to-Person (GTP) - Includes conveyor belts, carousels, and vertical lift systems designed to cut the time required to complete order fulfillment activities.

Automated Storage and Retrieval Systems (AS/RS) - Using computerized systems to facilitate the retrieval and movement of goods from storage.

Automatic Guided Vehicles (AGVs) - Robots following a fixed warehouse path.

Autonomous Mobile Robots (AMRs) - Robots that navigate through a warehouse using GPS.

Pick-to-Light and Put-To-Light Systems – Use mobile scanning devices synced to digital lights to help workers locate or place items.

Voice Picking and Tasking – Uses speech recognition software to eliminate the need for handheld devices, increasing efficiency and safety for workers.

Warehouse logistics is one component of supply chain logistics. They are reliant on each other and interconnected. That makes it crucial for eCommerce companies to not only manage their warehouses effectively but also to gain control over their supply chain – and integrate the two pieces.

Real-time supply chain visibility is tracking goods and their exact location at any given point. Increasing supply chain visibility can help companies quickly pinpoint potential problems and resolve them before they snowball. And, of course, that improves a company's ability to satisfy its customers, cut costs, and improve its profitability.

Achieving real-time supply chain visibility requires specialized tools, including RFID tags, GPS tracking, and sensors. In essence, these tools help businesses always gather real-time data about the location and condition of goods. Having access to this information gives businesses a greater ability to see the big picture of their logistics and supply chain and pick out the parts that aren’t working as well as they could.

One of the most important goals of warehouse logistics is the ability to get products to the consumer quickly and efficiently. Because of the growing demand for two-day, one-day, or even same-day delivery, eCommerce businesses focus more on just-in-time inventory management, or JTI.

Inventory management helps businesses balance inventory with demand. Keeping too much inventory on-hand costs money – a vital asset for retail companies.

Instead of tying up operating dollars in stock just sitting around and taking up space, eCommerce companies are using JTI to help them keep enough stock on hand to meet current demand without worrying about stockouts and lost sales.

Just-in-time inventory management can help businesses by:

The BUKU app is a tool that is helping companies worldwide to increase their efficiency and save money on their logistics processes. They offer a wide range of features and services designed to help eCommerce businesses get the most from their shipping dollars, automate tasks, and better understand their warehouse logistics.

BUKU offers a one-of-a-kind experience for businesses, including access to dynamic shipping rates from a wide variety of carriers. This ensures your business will always get the best price, and your customers will have options and absolute visibility into the process.

BUKU also offers features that help track packages through the fulfillment process all the way through delivery. As well as access to detailed reports and intuitive data analytics so businesses can make the best decisions regarding their logistics processes.

Warehouse logistics benefits the customer – which is the best way for eCommerce businesses to stay ahead of the competition and build a loyal base. All the activities behind the scenes in a warehouse are put in place to ensure that customers receive their deliveries quickly, accurately, and efficiently.

Those customers might not understand the complexities of logistics and how it affects them. Still, they will certainly take notice when a poorly run logistics system affects their ability to get their package on time.

Ecommerce businesses can take steps to ensure that their warehouse logistics support customer loyalty and satisfaction by always keeping the customer in mind. There are many moving parts to a supply chain and within a warehouse. Remembering that the goal is to satisfy the customer is critical to making the right decisions.

A well-orchestrated warehouse management system will help businesses by:

Technology has never been more prevalent in business, and considering the innovation of the past century, that’s saying something. Every day, advancements are being made in the field of automation, AI, machine learning, and other technologies that can help businesses do more with less and do it much better.

So, what does the future hold for warehouse logistics and eCommerce? With 38% of businesses looking to optimize their supply chain technologies actively, technology is sure to play a huge role. Let’s look at some ways technology is advancing the goals and objectives of eCommerce.

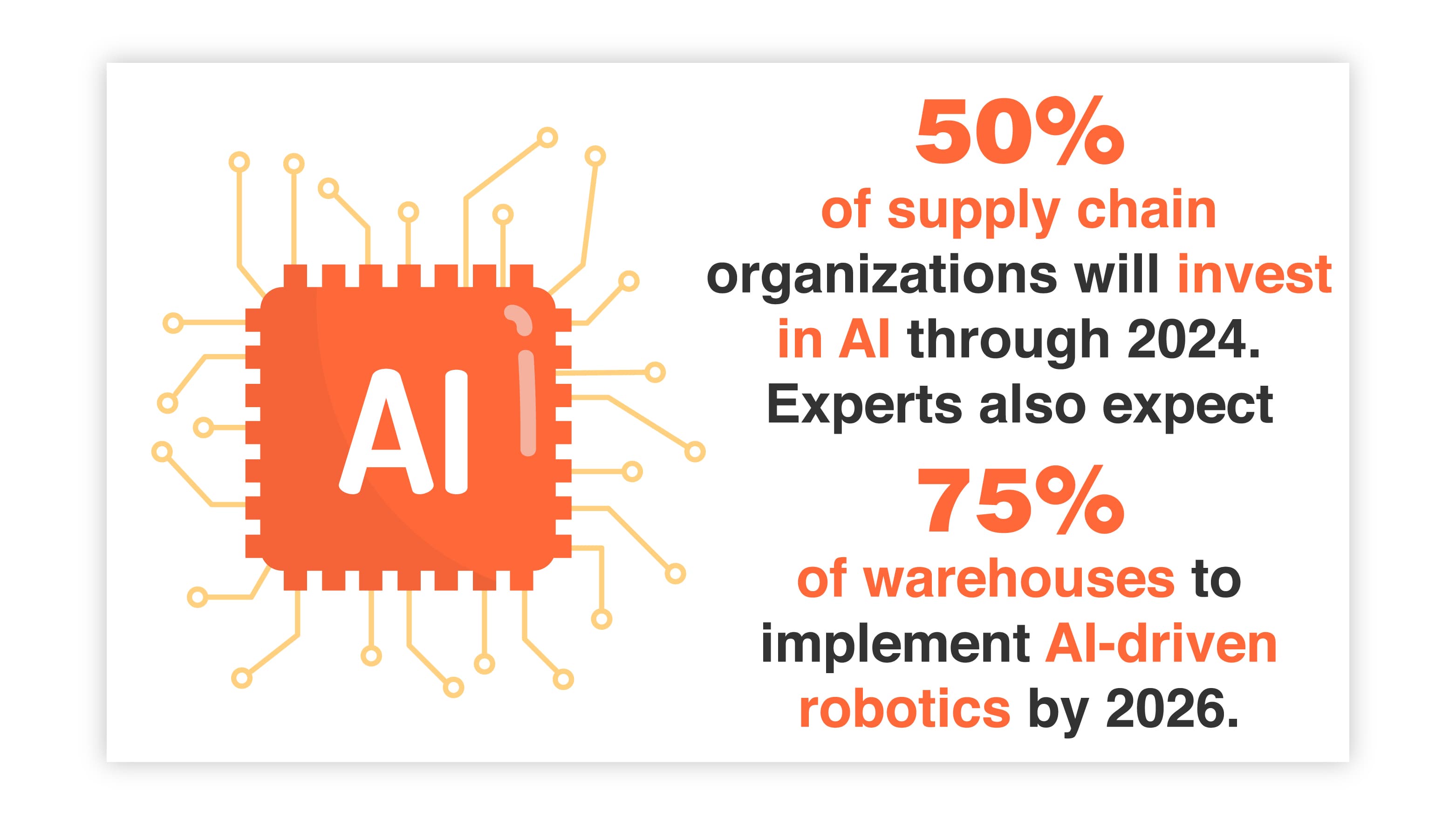

AI and ML are becoming more prevalent in the retail industry because of their ability to help business owners see into the future.

These two technologies can help create predictive tools which give businesses an edge in balancing inventory levels and demand. But the possibilities go much further than that and include streamlining and automating virtually every activity within a warehouse.

The statistics back up this trend and include that 50% of supply chain organizations will invest in AI through 2024. Experts also expect 75% of warehouses to implement AI-driven robotics by 2026.

Blockchain is making its way into the retail industry because it enhances and secures sensitive information and data tracking. It’s a technology that has already made waves in the financial industry, and the market is expected to experience a CAGR of almost 40% through 2027.

In the eCommerce and retail industries, blockchain has the potential to reduce fraud and diminish the prevalence of costly errors.

The Internet of Things is used to connect multiple components within an organization. Of course, the details of the process are much more involved than that, but just that simple definition gives a clear idea of how the IoT can benefit warehouse logistics and the supply chain.

Think streamlining warehousing operations and systems, better access to real-time data, system integrations, and more. Imagine an interconnected fleet system for transportation and delivery that can track weather events and traffic in real-time. The IoT has so many uses that are already in place, and many more that are just being explored.

When implemented correctly, warehouse logistics have incredible potential to help businesses remain competitive in a market that is increasingly saturated and cutthroat. It can help optimize operations so that costs remain as low as possible. It can help businesses eliminate waste whenever and wherever possible.

It can streamline the flow of goods within a warehouse to meet business needs and objectives. And more important than anything, it helps eCommerce businesses build a system that ensures customers are satisfied.

With so many moving parts and activities happening at once within a warehouse, careful planning and strategizing are vital. And that’s where warehouse logistics can make the difference. Putting the right tools and technology in place will ensure businesses are well-positioned for success today and well into the future.

If you’re looking for the best system to help you build a successful and competitive eCommerce business, then BUKU’s app is a must-have. BUKU has built an easy-to-implement and intuitive design that includes all the features required to make a proper warehouse logistics program, optimize shipping and delivery processes, and save money for the business and its customers. Check it out today and put yourself on the road to success.

The supply chain is a term used to describe all the components required to transport goods from beginning to end, from production to the end...

A smart warehouse is a large building where raw materials and other consumer goods are stored using machines, computers, comprehensive software, and...

Direct-to-consumer (DTC) fulfillment is a strategy that helps brands sell and deliver their products directly to customers more efficiently while...